Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGYAxial cracking in bearing races has become all too common in large megawatt turbines. This damage can shorten bearing life to as little as one to two years. Recent research suggests a root cause of axial cracking, making prevention and early detection possible.

Doug Herr • General Manager • AeroTorque Corporation

David Heidenreich • Chief Engineer • AeroTorque Corporation • www.aerotorque.com

Modern wind turbines are an important piece of our energy mix. Unfortunately, gearbox life issues have impacted their financial payback. Axial cracks in bearing raceways have become a major cause of premature gearbox failures in the latest generation of wind turbines. However, it’s rare to find axial crack failures in gearbox bearings in other industries. Why damage is so common in wind turbines has been a mystery and the subject of intense research. The root cause must be understood before finding a solution.

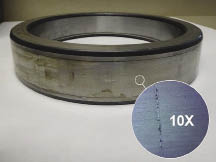

A single axial crack has propagated completely through the inner ring.

The first part of this article reviews the latest research on axial cracking and provides a discussion on how axial cracks grow from smaller cracks that have a white color when sectioned and etched. White Etch Cracks (WEC) originate from microscopic super-hard areas that also show up white when sectioned and etched. These areas in which cracks start are called White Etch Area (WEA) damage. A few recent papers suggest that a threshold of rapid and severe plastic deformation must be exceeded to create these hard microscopic WEAs. But what event in a wind turbine could cause such rapid and severe bearing loads? The second part focuses on this subject and is based on recent research and field monitoring by the authors that was presented at NREL Gearbox Reliability Collaborative in February, 2013, along with additional research and field data collected since that presentation.

Axial cracking

Axial cracks on inner rings of high speed and intermediate speed bearings have become a leading cause of wind turbine gearbox life issues. Many technical papers on axial cracking in the past couple of years have focused on why this unusual bearing phenomenon is so prevalent in wind turbine gearboxes.

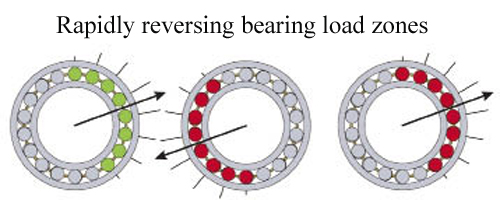

Aligned (green) rollers are in a load zone. Misaligned rollers (red) are 180° to the loaded ones. In a transient torque reversal, unaligned rollers are suddenly loaded, then unloaded, and repeatedly in a short period.

Aligned (green) rollers are in a load zone. Misaligned rollers (red) are 180° to the loaded ones. In a transient torque reversal, unaligned rollers are suddenly loaded, then unloaded, and repeatedly in a short period.

Wind-turbine bearings are selected to meet a 20-year design life, with a low likelihood of failure. Most manufacturers follow Germanischer Lloyd guidelines for gearbox bearings. GL requires analyzing gearbox bearings for Rolling Contact Fatigue (RCF) resulting in a calculated life of at least 130,000 hours with a likelihood of failure at less than 10%.

The early stages of multiple axial cracks appear on the inner ring.

If a gearbox meets these design criteria, how can axial cracking failure rates be so high and often occur within the first or second year of operation? How can it be that a bearing that has been analyzed using well-understood and validated methods likely fail much sooner than predicted? The answer lies in the fact that the axial cracking failure mode differs from the classic RCF failure mode. RCF failures are caused by damage to the bearing material that accumulates over time at well-understood rates. Axial cracking failures are relatively recent phenomena and their failure modes are much less understood.

Axial cracking failure mode of a bearing mainly occur on the inner ring typically mounted to a shaft with an interference fit. The ring is heated during assembly onto the shaft. When the ring cools, it shrinks – holding the ring in place, but also creating tensile stress in the ring that increases the possibilities for axial cracking. An axial crack failure of the inner ring can be caused by excessive hoop stresses during installation but this does not appear to be the general case in the wind industry. Microscopic, white-colored areas at the edge of the cracks when the bearings are sectioned and etched are a key indicator that this is not merely standard hoop-stress failures. These cracks are termed WEC and are commonly found in through-hardened bearing races. When WEA damage causes flaking or spalling, it may be termed White Structure Flaking (WSF). This generally occurs in carborized raceways. Either way, the damage starts with the creation of WEAs.

WEA – a subsurface microscopic material alteration

Detailed failure analysis of axially cracked bearings reveals that the WEAs not only appear in surface cracks but also in subsurface cracks and even areas where cracks have not yet started. WEA damage is actually a microstructural alteration of the inner ring material, creating tiny super-hard areas (30 to 50% harder than the surrounding area) just below the raceway surface. These areas act like inclusions in the steel.

White Etch Cracks and White Surface Flaking appear on the inner ring of a tapered roller bearing. Evidence suggests that both were initiated by WEA microstructural alterations in the steel subsurface. Courtesy A. Greco et al 1

Once an event initiates subsurface WEA formations, normal rolling action of the bearing can initiate cracks at the junction of these inclusion-like areas. The crack inevitably propagates to the surface and becomes a WEC, which grows axially across the raceway and causes premature bearing failures.

Many research papers recognize two primary mechanisms for WEA damage: hydrogen-induced WEA and stress-induced WEA. Hydrogen WEA is believed to be driven by corrosion, water contamination, electrical currents or aggressive oil additives that can worsen cracks once they appear on the surface. But what events initiate these surface cracks? This article focuses on understanding the events that can initiate subsurface stress-induced WEA damage but it will also show how these same events could cause the cracks where hydrogen-induced WEA can happen too.

A microscopic WEA formation with nano hardness measurements showing a 44% increase in hardness.

Courtesy A. Greco et al 1

Stress-induced WEA damage in the bearing inner ring comes from an event that causes the roller to exert high subsurface stresses simultaneously with rapid strain rates. Possible WEA mechanisms mentioned in recent research includes:

• Impact loading – sudden loads that can cause high stress and strain

• Surface traction – frictional contact between the rollers and races that produce high surface and subsurface stresses

• Severe plastic deformation (SPD) – subsurface stress high enough to cause microscopic deformation

• Rapid plastic deformation (Adiabatic Shear Bands – ASB) – subsurface plastic deformation so rapid that the heat generated cannot dissipate and thus directly alters the material to create ferrite microstructures.

These four mechanisms are related and can occur at the same time. For instance, WEA damage can be created in the lab with ballistic impacts, where all four of these WEA mechanisms have been shown to act simultaneously.

Impact loads, and rapid and severe plastic deformation

An Adiabetic Shear Band, or ASB, is an area within a base material transformed by microscopic, localized heating during rapid and severe plastic deformation. Since the 1960s, ASBs have been studied extensively because of their importance as a failure mode in areas such as high-speed metal forming and cutting, various types of ballistic impact, as well as vehicle crashes. Adiabatic, a thermodynamic term, simply means an absence of heat transfer – heat produced is retained in the zone where it is created. These shear bands are usually narrow, about 0.0002 to 0.020 inches. In steel, these bands are in fact WEA damage initiated by fatigue cracks. There is a threshold of instantaneous high stress and strain rate where microscopic plastic deformation creates heat so fast that it cannot escape. The subsurface metal momentarily softens and transforms the material as it cools into an altered microstructure. Severe deformation that occurs slowly lets heat escape and does not produce ASBs or WEA damage. Thus, a stamped metal part may show a similar degree of plastic deformation as a bullet hole, but if the strain rate is slow enough the stamped part avoids ASBs and WEA damage.

Left: The red trace plots a high wind TTR event on a 2 MW wind turbine. At about the 17 sec mark the torque rapidly transitions from positive to negative. This torque transfers right through the gearbox bearings.

Right: The red trace plots a high wind TTR event on a 1 MW wind turbine during an emergency stop. At about the 15 sec mark the torque oscillates from positive to negative.

In bearing material, the heat from the rapid plastic deformation can cause a microstructural transformation of the hardened bearing steel into a sliver of super-hard ferrite that appears white when sectioned and etched– WEA damage. A band of WEA damage, however, is not required to fail the bearing. A single sliver of this WEA damage can act as an inclusion to initiate WEC that eventually propagates to the surface and across the bearing raceway surface.

Bearing manufacturers have continuously improved the life of roller bearings by improving the purity and quality of the steel used in their products. By minimizing hard inclusions and stringers (elongated carbide or sulfide inclusions), manufacturers minimize the potential places where cracks initiate and propagate. These efforts have gained an impressive 10-fold increase in bearing life as predicted by the standard RCF method used by bearing manufacturers to calculate L10 life. Unfortunately, all the efforts to make super-clean steel are wasted by events in a wind turbine’s operation that initiates WEA damage, mimicking inclusions less than 0.04 inches (1 mm) below the raceway surface. This depth coincides with the depth of maximum shear stresses under the bearing raceway during normal Hertzian loading of the rollers. This is also the worst possible location for an inclusion-like impurity – leading to shortened bearing surface fatigue life and axial cracks. Once started, WEA damage can reduce bearing life to just 1 to 10% of predicted life as calculated with standard rolling-contact-fatigue formulas. This explanation shows how WEA induced axial cracks can cause bearing failures within a few years of operation.

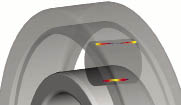

The yellow and red areas identify highest stress locations in a bearing during transient torque reversals.

What events in a wind turbine could create impact loads and rapid plastic deformation significant enough to initiate the WEA damage? A recent NREL paper concluded, “A wind turbine exposed to an extreme event, such as a power loss or emergency stop, could produce the localized deformation energy needed for ASB formation.”

Emergency stops and other transient turbine events

Recent research on bearing axial cracking suggests that impact loading, and emergency stops as likely contributors to WEA damage. Wind professionals have long recognized a connection between sudden stops, and extreme loading into all turbine-drive components. Many have also noted a relationship between emergency stops and gearbox life. Furthermore, there is a growing awareness that it is the Transient Torque Reversals (TTRs) during severe stopping events which may be the source of damaging impact loads in gearbox bearings.

Some drive systems in other types of equipment see severe transient loading and torque reversals without experiencing WEA damage to their bearings. Severe torque loads without reversals, and torque reversals that happen slowly in a controlled manner, would not create rapid plastic deformation in the bearing raceway. Wind turbines, however, are different. Why? Their drive systems are unique in the severity of torque reversals and most importantly, the rapidity at which they happen.

In gearboxes with helical-gearing, simultaneous radial impact and axial loading of a misaligned roller is known to decrease bearing life.

Rapid torque reversals

What is it about a turbine drivetrain that causes it to be so susceptible to the rapid and severe torque reversals? This has to do with the relative rotating masses (inertias) of the blades and the generator rotor, and how they can react against each other within the torsional natural frequency of the drive system. A typical turbine has 80 to 90% of its relative inertia in the blades, with most of the rest of the inertia in the generator rotor. In normal operation, the blades are driving the generator in the positive direction. A grid disconnect, emergency stop, or high-wind shutdown triggers rapid aero braking of the blades that attempts to decelerate the drive system. Most of the aero braking effort goes into decelerating the massive blade inertia, but some of it goes through the drive system to decelerate the generator. This typically causes a torque reversal in the drive system that can result in the inertias of the system winding up and unwinding against each other several times at the torsional natural frequency of the system as it decelerates. Note: The 1 and 2 MW turbines have similar natural frequencies despite the significant size difference in the turbines. How do these reversals cause impact loading in the bearings?

Rapidly reversing bearing load zones and impact loads on misaligned rollers, damaging to bearings in other types of equipment, can cause WEA damage. Rapidly reversing bearing load zones are also known to decrease bearing life. During TTRs, every bearing in the gearbox sees a rapid load zone reversal of almost 180° that can cause severe impact loads between rollers and raceways. All the cited research recognizes that impact loading could be the source of the stress-induced subsurface WEA damage, and most of the findings name it as a suggested leading candidate.

Field testing demonstrates the ability to reduce the maximum reverse torque and rate of torque increase. This method can also dampen torsional vibrations to reduce the number of reversals to 40% of nominal torque.

During normal operation, rollers in the bearings are aligned and rolling at the expected or design speed while they are in the load zone. As they leave the load zone, the rollers slow down and can misalign within the tolerance of the cages. As they approach the load zone again, they are gradually brought back into alignment and smoothly accelerate to support the load. In a rapid load zone reversal, the unloaded rollers opposite the normal load zone are suddenly loaded while in this misaligned state. This rapid loading increases the load concentration of the rollers in the middle of the inner race.

Although load reversals are common to many types of equipment, torque reversals of the magnitude and rapidity common in wind turbines is rare in other equipment. And helical gearing commonly used in wind-turbine gearboxes adds additional subsurface stress and strain. With helical gearing, every cylindrical bearing will see high axial loads simultaneous with the radial loads impacting misaligned rollers. Cylindrical rollers may slip axially and damage the raceway surface, further decreasing bearing life through pitting and spalling. Sliding can also result in scuffing the raceway, causing microscopic cracks that let subsurface entry of water or aggressive oil additives to initiate hydrogen induced WEA.

If the radial impact load is so high that the roller breaks through the oil film, it can create mixed friction sufficient to prevent slipping axially. Axial subsurface stresses will be added to the Hertzian stresses from the radial impact, magnifying the peak stresses. The strain rate would be magnified as well. The potential to exceed a threshold where WEA microstructural alterations could form, explains why WEA damage is common in wind-turbine gearboxes and rare in most other bearing applications. Tapered-roller bearings can also be damaged by the affects of load reversals. Those used on high and intermediate-speed shafts typically are not preloaded due to thermal constraints, and can see damaging axial movement and impact loads.

High-resolution torque reversal recordings of wind turbines reflect the rate of change in torque. The steeper slope indicates significantly higher strain rates.

Axial cracking issues in bearings were not a prominent failure mode until larger megawatt and multi-megawatt class wind turbines were put in service. It was not a common failure mode of earlier, smaller turbine models where the failure mode was more commonly bearing surface deterioration from pitting and scuffing. The issue of axial cracking grew along with turbine size.

To understand why, it is important to zoom in on the field data to look at the first quarter of a second of the worst torque reversals that were recorded on three different size wind turbines. The graph Comparison of torque reversals recorded on three different sizes of wind turbines compares the relative torque magnitude and the rate of torque change during rapid reversals. High-resolution torque monitoring equipment recorded torque reversals that approximated the turbine rated torque at the high-speed shaft on 0.75, 1, and 2 MW turbines. The torsional natural frequencies of the turbines during aero braking were all similar with oscillation periods about 0.75 second-per-cycle. Higher torque loads of the larger turbines can be accommodated in the sizing of the bearings but the oil film thickness will not increase. Any roller misalignment easily causes higher local-contact stress during a torque reversal. The difference in the rate of increase of the reverse torque during the torque reversal may be an even bigger factor, as it directly relates to the strain rate in the raceway as the rollers impact. Both the higher stress and the faster strain rate increase the instantaneous plastic deformation energy.

There is a threshold in plastic deformation energy where the instantaneous heat created causes the microstructural alteration of the base material. Could the increasing strain rate of larger turbines be exceeding that threshold? During rapid load zone reversals, could the rapidly increasing load on the rollers create plastic deformation fast enough to transform a microscopic sliver of the bearing steel to a super-hard ferrite WEA inclusion? Certainly all the elements for WEA microstructural alterations are simultaneously present for an instant. The torque reversal takes up the gear backlash and rapidly impacts the idling rollers on the unloaded side of the bearing. The misaligned rollers can make the stress concentration and the plastic deformation under the rollers worse and initiate mixed friction contact. Simultaneous reversal of the axial load due to the helical gearing causes surface traction and additional stress at the inner-raceway subsurface. The resulting high-strain rates and plastic deformation can explain the creation of the WEA microstructural transformation.

In a typical power curve, pitchable blades let modern wind turbines perform close to an ideal power curve. Blade orientation and control lets turbines maximize the energy generation.

Because the WEA sliver is perfectly placed under the raceway surface, one microscopic sliver would be enough to initiate the WEA damage that would result in an axially cracked, failed bearing. All it takes is one moment to exceed the combination of high load and strain-rate threshold. That event could come from one severe e-stop, a combination of an e-stop with a wind gust, high-wind shutdown, control malfunction, or sensor failure. Some researchers say torque reversals create loads up to 2½ to 4 times nominal torque. That would be 2½ to 4 times the torque loads shown in Comparison of torque reversals recorded on three different sizes of wind turbines. Furthermore, if the natural frequency is unchanged, the strain rate would be 2 ½ to 4 times higher, as well. Every doubling of the torque magnitude, with the same natural frequency, may effectively quadruple the instantaneous deformation energy that causes WEA damage.

Rapid and severe impact loading of the rollers on the bearing raceway can cause stress-induced WEA damage, significantly shortening the life of bearings and gearboxes. There are three ways to address the problem:

For protection during high winds, a turbine will use less than 10% of the available power as winds approach the typical cut-out speed of 25 mps. The turbine’s blades will pitch to a precise angle to effectively spill wind power to avoid excessive loads.

1. Strengthen the system or components to reduce the degree of damage by:

a. Changes in raceway material, processing and coatings

b. Changes in bearing type

c. Improved lubrication and oil additives

2. Try to detect the damage and replace the bearings before catastrophic failure by:

a. More frequent borescoping

b. Better conditioning monitoring

3. Solve the root cause by preventing the excess stress and strain rate from happening by:

a. Adding an asymmetric torque limiter

Ongoing research should prove the relative value of these solutions in extending bearing life. Some proposed solutions may incrementally extend life or prevent catastrophic failures with early axial crack detection. The asymmetric torque limiter addresses the root cause – the rapid and severe loading that can initiate the stress-induced WEA damage. Simple frictional slip torque limiters are commonly used to protect wind turbine drive systems from severe torque overloads, such as generator short circuits. No evidence, however, has been found that such a basic torque limiter can provide protection against axial cracking. An asymmetric torque limiter has a much lower slip setting in reverse. Field testing of wind turbines with and without the asymmetric torque limiter has demonstrated its ability to significantly reduce the maximum reverse torque and rate of torque increase, thus maximum stress and strain rate caused by the rollers impacting the bearing raceway during the torque reversal. This approach also dampens torsional vibrations to reduce the number of reversals.

The red dotted trace plots the torque reversal magnitude and rate of change for a 750 kW turbine without asymmetrical torque control. The blue trace plots the same with an asymmetrical torque control in place and shows its effectiveness in reducing maximum reverse torque, and rate of the reverse torque increase.

Field data from a 750 kW turbine shows the effectiveness of the asymmetrical torque control in reducing the maximum reverse torque and the maximum rate of reverse torque increase. The magnitude of the stress and maximum strain rate of the rollers impacting the raceway are reduced by over 50%. That translates to a 75% reduction of the instantaneous impact and deformation energy.

On larger turbines, this deformation-energy reduction comes in a similar manner with the likely outcome of significantly reducing axial cracking. If asymmetric torque control keeps impact loads below the threshold where WEA microstructural alterations are initiated, super-hard WEA slivers could never form under the raceway, and axial cracks in gearbox bearings would cease to be a prominent mode of failure affecting the cost of wind-turbine energy. WPE

Blade dynamics – Not all e-stops are the same

How emergency stops with high winds, turbulence, or gusts can magnify torque reversals and bearing impact loads

Pitchable blades let modern wind-turbine models perform close to an ideal power curve. Blade pitch control is important to maximizing the energy capture from the wind. Additionally, it is critically important as the primary safety braking system for protecting the turbine from high-wind speeds damaging wind loads and overspeed in the event of turbine subsystem failures.

The graph Typical power curve and blade pitch angles also shows the pitch angles of a typical modern turbine. At low-wind speeds, the blades are in a fully feathered position about 90° to the plane of rotor sweep. In region II, the blades rotate to about 0° pitch angle to extract the maximum power, capturing close to 50% of the wind’s available power. In region III, the blades are pitched back to protect the turbine from high stresses as it strives to control and maintain full-rated power. At cut-out speed, the blades are quickly pitched to provide braking to safely decelerate and shutdown the turbine drive system.

The graph Power vs. wind speed of the power curve masks the challenge of protecting the turbine from damage during high and turbulent winds. The Strain rate analysis graph shows the turbine power curve compared to the wind’s available power. As the winds approach the typical cut-out speed of 25 mps (55 mph), the turbine may use less than 10% of the wind’s available power. The blades must be pitched to a precise angle to effectively spill wind power equal to 10 times the turbine’s rated power and protect the drive from excessive loads. With longer blades, the cut-in speed and the rated power speed is obtained at even lower wind speeds, significantly improving annual energy output and financial performance projections while also increasing the challenge of controlling excess wind loads.

At high winds, the blades are already pitched back 20 to 30° to spill most of the wind power. During a grid loss or e-stop, the blades rapidly pitch further to decelerate the turbine. This is when the potential for torque reversals and bearing impact loads is at its worst pontential. The highest winds tend to occur during stormy weather when wind gusts and turbulence are high and the possibilities for grid loss and e-stops are greatest. High-wind shutdowns and e-stops during gusty winds create a perfect storm for drive system torque reversals and damaging impact loads to bearings. The worst torque reversals AeroTorque has recorded occurred during high wind shut downs in stormy conditions. WPE

FOR FURTHER READING

[1] A Greco, PhD, et al., Bearing Reliability – White Etching Cracks (WEC), Argonne National Laboratory, Energy Systems Division, NREL Gearbox Reliability Collaborative, Feb 4 (2013)

[2] M.-H. Evans, White Structure Flaking (WSF) in Wind Turbine Gearbox Bearings: Effects of Butterflies and White Etching Cracks (WECs), Material Science and Technology 28 (2012) 3–22.

[3] A. Greco, et al., Material Wear and Fatigue in Wind Turbine Systems, Wear (2013), http://dx.doi.org/10.1016/ j.wear.2013.01.060i

[4] Kenred Stadler, Arno Stubenrauch, Premature Bearing Failures in Industrial Gearboxes, SKF GmbH, Gunnar-Wester-Str. 12, 97421 Schweinfurt, Germany

[5] J. Rosinski, D. Smurthwaite, Troubleshooting Wind Gearbox Problems, Gear Solutions 8 (2010) 22–33

[6] Rob Budny & Robert Errichello, How To Minimize Axial Cracking Failures, North American Windpower, June 2013

[7] Jean Van Rensselar, Extending Wind Turbine Gearbox Life, Tribology and Lubrication Technology, May 2013