Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGYWHAT IS TRIBOLOGY?

Tribology is the science of wear, friction and lubrication, and encompasses how interacting surfaces and other tribo-elements behave in relative motion in natural and artificial systems.This inclues bearing design and lubrication.

Tribology is not an isolated science, but rather a complex, multidisciplinary endeavor where advances are made by collaborative efforts of researchers from fields including mechanical engineering, manufacturing, materials science and engineering, chemistry and chemical engineering, physics, mathematics, biomedical science and engineering, computer science, and more.

WHAT ARE THE FUNDAMENTALS OF TRIBOLOGY?

One of the most important pillars of tribology is the system analytical and system related thinking.

Tribological systems 123

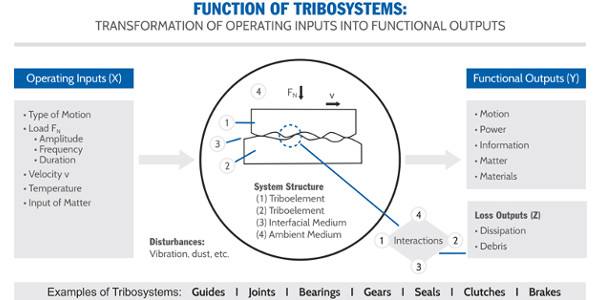

Friction and wear are not material properties. They are responses to a specific tribological system which typically includes a bearing, shaft and lubricant combination and as such are influenced by a wide range of factors. The tribological sub-system in Figure 1 provides an overview of common factors which affect friction and wear values:

This tribological system is composed of the collective stress/operational inputs, system structure and the functional and loss outputs. The collective stress includes the technical and physical load parameters including load, sliding speed and duration along with the movement and temerature conditions stressing the system-structure. The system-structure is determined by the property profiles of the substantial elements including the base, opposing body and ambient and the intermediate medium.

This tribological system is composed of the collective stress/operational inputs, system structure and the functional and loss outputs. The collective stress includes the technical and physical load parameters including load, sliding speed and duration along with the movement and temerature conditions stressing the system-structure. The system-structure is determined by the property profiles of the substantial elements including the base, opposing body and ambient and the intermediate medium.

WHAT ARE THE PRIMARY CHALLENGES A TRIBOLOGIST CONFRONTS?

The greatest challenge is that friction and wear values cannot be easily transferred from one system to another eg from a tribological test rig to a real application. Comparisons between measured values are only feasible when based on a very similar tribological system. The tribological behavior of materials can ony be estimated for specific applications based on modeling and simulation testing provided the specific operating conditions of the application and test environment are the same.

FRICTION AND WEAR (1)(2)(3)

What is friction?

Friction is the force of resistance to motion between two bodies in contact. Friction can be described on the macroscopic level by the basic laws of friction from physicists Guillaume Amontons and Charles-Augustin de Coulomb. These physicists found a linear relationship between resulting friction force and applied normal load. Based on this, a dimensionless main parameter can be derived, called the coefficient of friction. It is defined by the ratio of the resulting friction force and applied normal force.

However, the actual mechanism of sliding friction occurs at a microscopic level, which means tribological theories on friction also involve the topography of the surfaces. The tribologist differentiates between the real contact area and the nominal contact area (geometric dimensions), which accounts for any voids or non-contacting portions of a solid element. The mechanisms responsible for the energy transforming process in the near surface area include:

What is wear?

Wear is defined as the irreversible material loss of interacting surfaces. Physical and chemical elementary processes within the area of contact of a sliding pairing subsequently leading to change in material and shape of the friction partners are known as wear mechanisms. These wear mechanisms include:

Friction and wear mechanisms are strongly affected by the structure of the tribological system as well as on the induced collective stress:

Friction and wear mechanisms are strongly affected by the structure of the tribological system as well as on the induced collective stress:

µ=f(tribo-structure(t),induced collective stress(t))

w=f(tribo-structure (t),induced collective stress(t))

Friction and wear mechanisms do not occur in an isolated fashion, but rather through a superposition of mechanisms that is challenging to quantify and control for. This superposition occurs in tribo-technical systems in non-detectable proportions and in proportions that vary across time and place, making it nearly impossible to calculate friction and wear processes in a tribo-contact. This is why tribological tests are so crucial for estimating tribological behavior. If we want to interpret and understand tribologically-measured data and mechanism-oriented research, we need complete knowledge of the acting mechanisms in a tribo-contact.

Tribologists classify friction, wear and lubrication conditions according to the following schedules:

Friction Regime 0: Solid friction: Friction is created between direct contacting solid surfaces without any lubricant. Friction Regime I: Boundary friction: Solid friction, in which the surfaces of the friction partners are covered with a molecular lubricant film that has no load carrying capacity. The Lubricant has an influence on the friction and wear characteristics. Friction Regime II: Mixed friction: Friction regime I and III co-exist. The friction value is a combination of solid and hydrodynamic friction. A fluid film created by the lubricant has a load carrying capacity. Friction regime III: Hydrodynamic friction: Friction value is determined by shearing in the fluid. The load carrying capacity of the fluid film prevents direct contact between the two solid surfaces. Wear regime a: High wear rates due to solid friction and direct contact of surfaces. Wear regime b: Lower wear values due to a molecular fluid film. Wear regime c: Mild wear due to a partial separation of the surfaces through a thicker fluid film. Wear regime d: “Zero wear,“ resulting from hydrodynamic or elastohydrodynamic fluid films that prevent direct contact of the two surfaces.

WHAT OUTCOMES CAN BE ACHIEVED BY APPLYING TRIBOLOGY TO BEARING DESIGN?

How can Tribology lead to measurable product improvement?

Tribological testing allows us to gain information about tribo-performance of materials to drive new and better material designs. We can then target material compositions to achieve specific and better tribological properties.

Tribological test results and surface analytical methods help us estimate the tribo-performance including friction and wear, failure mechanisms, kinetics of transfer films of existing materials and new prototypes based on various factors and influences. This information helps us see and understand variables like the effects of various material compositions including filler, filler concentration, synergetic effects of fillers, material structure as well as the impact of other elements of they system structure.

How does Tribology improve efficiency and extend service life of bearing materials?

Tribologically optimised contacting surfaces

Identifying critical factors influencing the tribo-system Identifying solutions to improve efficiency and reducing wear, including: Use of friction and wear optimized materials. Optimizing material pairings, which leads to low friction and wear levels. Selecting and using the correct lubricants. Arriving at design changes that have a beneficial impact on overall tribo-system performance.What are some examples of bearing technology advancements tribological research has delivered?

For an overview of the historical advancements in bearing technology driven by tribo-research, read this article in Eureka Magazine. It covers rudimentary roller bearings used by the ancient Egyptians, ball bearings used by the Romans 40BC, the roles of heat treatment of hardened steel and oxide-based ceramics. It also covers he development of the first self-lubricating plain metal-polymer bearing by GGB.

In what industries and applications is tribology useful?

Tribology plays a central role in applications in which two contacting surfaces move in relation to each other. Some industries place higher demands on tribological systems due to their mission criticality, continuous operation requirements or extreme conditions.

WHAT DOES AN ENGINEER NEED TO THINK ABOUT WHEN DESIGNING PRODUCTS OR FRICTION/WEAR EXPERIMENTS?

This depends strongly on the application. Some applications require low friction (e.g. bearing materials) while others require high friction (e.g. brake systems). For most of the applications, minimum wear of the materials is a primary goal. For many applications, a defined sweet spot between low friction levels and good wear performance is often targeted.

When designing experiments describing friction and wear, tribological testing can be placed into one of six main categories, from field tests in Category I to simplest laboratory model tests Category VI.

Category I: A field trial is conducted under normal operating conditions, which may include extended operating conditions. This results in poor repeatability but is close to real world requirements the tribological system will face.

Category II: Experiments are undertaken with a complete piece of equipment in a plant environment. These experiments may achieve results close to normal operating conditions and can be conducted over a period of time to replicate extended operating conditions while limiting environmental impact.

Category III: Components, subsystems or assemblies are tested in a laboratory approximating normal extended operating conditions, yielding medium repeatability

Category IV: Laboratory testing is conducted on serial standard components using scaled down testing plant apparatus.

Category V: Experiments are conducted on a specimen with test equipment to deliver close to normal operating conditions with excellent repeatability.

Category VI: A bench test is conducted with simple laboratory test equipment.

It is important to remember that in categories I through III, the system structure of the original tribo- aggregate remains consistent, and only the collective stress is simplified. Categories II and III offer more reproducible collective stresses than category I. In contrast, in categories IV through VI, the system structure is simplified with the disadvantage of decreasing predictability in the transferability of test results to comparable practical tribo-technical systems. Categories IV through VI offer better metrology of the sub tribo-contact, lower cost and a tighter testing timeframe.1 So with an ascending order of the test categories the test time as well as the test cost increases significantly, but transferability of the test result increases as well.

How can we apply the test categories to the sub tribo-system bearing?

Tribological testing of bearing materials can be divided into four main categories:

Product performance descriptions, which would include categories IV and III to ensure the transferability of results. Production/Manufacturing monitoring, including categories VI through IV, with category III also being a possibility. Customer-related testing of bearings may include categories III through V, keeping in mind that category V is relevant only if the test can be adapted as close as possible to the application. All categories may be used to support material designers, with lower categories in the early stages of development for pre-selection and higher-numbered categories coming into play as the subcomponents and the final product are available. 1 Horst Czichos, Karl-Heinz Habig: Tribologie Handbuch: Tribometrie, Tribomaterialien, Tribotechnik, Vieweg+Teubner Verlag, 2010WHAT IS GGB’S APPROACH TO DEVELOPING BEARING SOLUTIONS THROUGH TRIBOLOGICAL EXPERTISE?

GGB develops tribologically optimized materials based on tribological results. We combine this knowledge of material science and performance with a thorough understanding of the tribological performance of our products and how they align with our customers’ application requirements.

WHAT ARE SOME OF GGB’S ACHIEVEMENTS IN THE FIELD OF TRIBOLOGY AS THEY APPLY TO BEARING SOLUTIONS?

In 2015, launched the HPMB® self-lubricating filament wound bearing with machinable liners and the GGB-SZ lead-free bimetal bearings. Launched a series of self-lubricating sintered bronze and sintered iron bearings in 2014, including the GGB-BP25, GGB-FP20 and GGB-SO16. GGB bearings played a part in the 2012 moon landing by the NASA Curiosity Rover. The self-lubricating DU® metal-polymer bearings serve as the primary suspension components for the rover’s drill spindle. In 2010, launched materials for superior performance under marginally-lubricated or dry conditions, including the lead-free metal-polymer materials DP10 and DP11. Launched a filament-wound product range for the European and Asian markets in 2009, including a strong, stable structure for high-load, low-wear requirements. New DX®10 bearings are recognized by winning the 2008 North American Frost & Sullivan Award for Product Innovation of the Year award in the Class 7-8 truck bearings category, awarded for excellence in new products and technologies in the industry. In 2003, introduced the lead-free DP31 metal-polymer material with improved performance under lubricated conditions and lower friction, better wear resistance and improved fatigue strength. Launched EPTM, a new range of injection-molded thermoplastic solid polymer bearings. In 1995, introduced the lead-free, steel-backed DP4 metal-polymer material to satisfy the needs of automotive shock absorbers and other hydraulic applications. Took on high-temperature applications with the 1986 launch of HI-EX® bearing material. Launched the first filament wound product range in the U.S. including GAR-MAX®, supporting high static and dynamic loads. In 1965, launched the marginally-lubricated DX® metal-polymer material for grease or oil-lubricated applications. In 1956, GGB introduced the DU®, the first steel backed metal-polymer bearing material with bronze and PTFE lining for excellent low friction and wear resistance. That same year, the company introduced the DU-B, with bronze backing for improved corrosion resistance. In 1887, Olin J. Garlock patented his first industrial sealing system to seal piston rods in industrial steam engines.HOW CAN TRIBOLOGY REDUCE OR ELIMINATE THE NEED FOR LIQUID LUBRICANTS?

Lubricants are a part of tribology, but in some cases the lubrication can be built into material of tribo-system components.

Material designers therefore create specific materials for dry lubrication conditions, achieving a superior tribological performance related to friction and wear with a reduction or elimination of liquid lubricants.

HOW DOES THE CONDITION OF A SHAFT AND THE TRANSFER LAYER IMPACT TRIBOLOGICAL PERFORMANCE?

Because the shaft is an essential element of the tribological system structure of the bearing sub-system. Its properties have a direct impact on friction and wear as well as on all other occurences in a bearing/shaft contact. Essential shaft properties include:

Materials and their chemical and physical properties Geometrical properties including topography and contact ratio.WHAT TRIBOLOGICAL FACTORS NEED TO BE CONSIDERED IN BEARING SELECTION? HOW DO THESE FACTORS AFFECT BEARING SELECTION?

The scope of the tribological system is of essential importance in bearing selection. A high level overview of considerations would include the following

1. The induced collective stress including:

Nature of the load Nature of the motion Temperatures Time factor2. The mating partner:

Materials, including physical and chemical properties Geometrical features including the contact ratio and topography (roughness, isotropy and anisotropy)3. The interfacial medium and its property profile

4. The ambient medium and its properties

5. Thermal conductivity of the construction.