Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGY

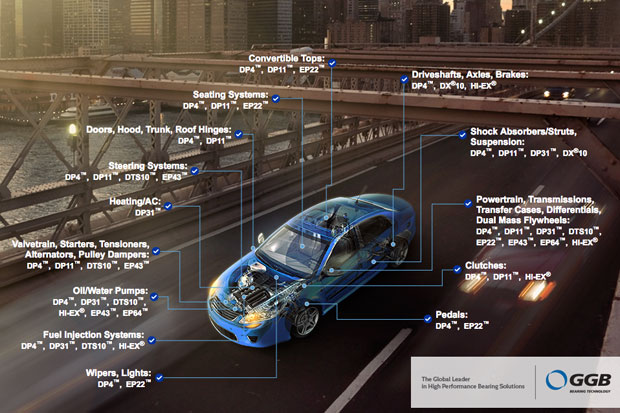

Even in the most demanding environments, customers benefit from the low friction, high wear resistance and the exceptional reliability of GGB automotive bearings for applications including wipers, convertible tops, interiors, struts, levers, pedals and many more including:

Steering Systems: yoke support, steering column, gear pump bearings Transmissions: rear output shaft, main shaft and reverse idler bearings, clutches, pumps, solenoids, planetary gear sets, gear shifting forks Seats: seat recliner and height adjuster mechanisms Axles: driveline systems, kingpins Brake Systems Hinges: door, trunk and hood hinges, door checkers Engine Management: water and oil pumps, belt tensioners, pulley dampers Struts and Shock AbsorbersWORLD-CLASS CUSTOMER SUPPORT

GGB’s Team of Experts offers superior customer service and technical support, providing customer specific automotive bearing design at both a global and local level. Worldwide, GGB supplies nearly all major Tier-1 and Tier-2 suppliers in the automotive and trucking industry in addition to many major OEMs.

Our range of first-class services includes in-house R&D, a reputable presence in automotive markets, worldwide representation and a broad range of bearing materials to ensure component functionality and performance. Thanks to readily available local supplies from our secure supply chain, our customers benefit from product reliability.

THE GGB ADVANTAGE OFFERS:

A wide range of high performance bearing materials and solutions to meet even the most demanding application requirements. GGB compact and lightweight solutions allow for the reduction of fuel consumption resulting in lower emissions. Continuous innovation of technologically superior products, systems and tools to keep us at the leading edge of high performance bearing technology. Comprehensive customer support thanks to our application experts who provide technical support and customer specific bearing design. A global strategy with local solutions and supplies. Customers benefit from our network of worldwide employees, global manufacturing facilities and a global supply chain.CONTRIBUTING TO A SUPERIOR DRIVING EXPERIENCE

In recent years, the operational requirements of automotive equipment have placed increased demands on bearing performance. GGB’s range of lead-free bearing materials with enhanced properties meet the most stringent performance requirements, offering significant advantages over rolling element bearings where space and weight are limited, or high loads and oscillating movements are likely to cause damage.

GGB automotive bearings offer many advantages, contributing to a superior driving performance:

Long life, reliable and smooth operation High wear resistant performance Self-lubricating Low coefficient of friction and break away torque, no stick-slip effect Compatible with most standard oils and lubricants High-precision and dimensionally stableELEVATED STANDARDS FOR QUALITY AND THE ENVIRONMENT

GGB environmentally friendly, lead-free bearings reduce installation, operating and maintenance costs and are compliant with the European Union’s End of Life Vehicles (ELV) directive on the elimination of hazardous materials.

GGB is certified to world-class standards for environmental management systems (ISO 140001) and for international quality management specification for suppliers of automotive components (ISO/TS 16949). These standards define the quality system requirements for design, development, production, installation and servicing of automotive-related products.

OUTPERFORMING THE COMPETITION

Product Leadership and Commercial Excellence give us the competitive advantage. GGB is able to provide customers with a viable replacement product, working alongside Tier-1 suppliers to global OEMs. Our experts can develop a design proposal and supply samples in a shorter time than the competition, outperforming all other proposals.

To meet our customers’ specific application needs, we offer a large selection of standard or custom bearings. GGB bearings provide good wear and friction performance over a wide range of load, speed and temperature conditions and the self-lubricating material offers excellent resistance to chemicals, cavitation, flow erosion and fatigue. GGB sub-assemblies give customers an optimized bearing design, simplified assembly and a reduced development time.

Download the GGB Automotive market brochure.

HIGH PERFORMANCE BEARINGS FOR AUTOMOTIVE