Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGYAuthor: Ciprian Radu

RKB Bearing Industries – Advanced Software Engineering Unit

Abstract: Bearing failures have great impact on industry and economy. The aim of the

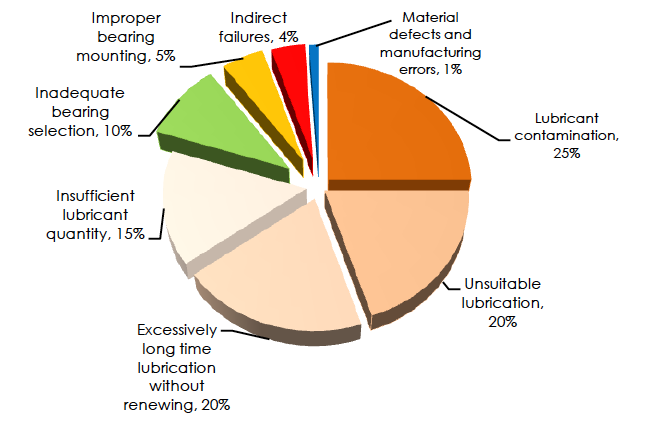

present work is to study and spot the major causes that limit bearing efficiency, thus leading to bearing failure. This study shows that the main failure cause is the inappropriate lubrication of the bearing rolling elements (approximately 80% of the cases), followed by inadequate bearing selection (10%), improper mounting (5%), indirect failure (4%), and material defects and manufacturing errors (less than 1%).

Key words: Bearing failure, Contamination, Grease, Oil, Lubricant, Lubrication

1. Lubrication of rolling bearingsThe rolling bearing is a machinery component that plays a very important role, since it dominates the machine performance. If one of the bearings fails, not only the machine, but also the assembly line stops and the deriving costs may be extremely high. For this reason, every bearing manufacturer should make every effort to ensure the highest quality for each bearing and the most careful use and maintenance on behalf of the user [10].

Lubricants are used between contact surfaces to keep the parts in continuous motion. The main purpose of rolling bearing lubrication is to avoid or reduce the metal-to-metal friction between the rolling and sliding contact surfaces. This is not the only function of rolling bearing lubrication. The supplementary functions are: heat dissipation from the bearing, removal of solid wear particles and contaminants from the rolling contact surfaces, corrosion protection, increase of the sealing effect of the bearing seals [4].

Lubrication is crucial for bearing life. In heavy duty applications, such as rolling mill machines, furnaces, ovens or high temperature fans, rolling bearings may be exposed to higher-than-normal temperatures. For these applications, appropriate selection of the lubricant and lubrication method is very important [13]. In industrial applications there are two types of lubricants suitable for high temperature use: grease and oil. In special cases, bearings are lubricated with solid dry lubricants [4].

Grease lubricant is used for 90% of all rolling bearings. The amount of grease to be used will depend on many factors relating to the dimensional and geometrical parameters of the housing, space limitations, bearing working speed and type of grease used. As a general rule, rolling bearings and their housings should be filled from 30 to 60% of their total capacity. If working speed and temperature rise, then a reduced amount of grease should be used. If the amount of grease is excessive, temperature rises, which may cause the grease to soften and local leakage may appear. With the passage of time grease loses its properties and fresh grease must be resupplied at proper intervals. The relubricating interval depends on the bearing type, dimensional parameters, bearing working speed and temperature [10].

In industrial applications, oil lubrication is used if adjacent machine components are supplied with oil as well, or if generated heat must be dissipated by the lubricant. The heat dissipation is necessary if high rotating speeds and/or high loads are involved or if the bearing is exposed to high temperatures [4]. In this case, the relubricating interval depends on bearing operational conditions (temperature, speed, load etc.), oil quantity and type of oil used. If an oil bath lubrication method is used when operating temperatures are around 50 °C, then the relubricating interval should be one year. For operating conditions of 70 to 100 °C, the oil should be replaced every three months. Anyway, it is important that lubrication system and deterioration be verified regularly to determine oil replacement [10].

Another type of bearing lubrication is solid or dry lubrication. This method is used in industrial applications, where rolling bearings are subjected to heavy loads, slow relative movements and high working temperature. Solid lubrication is very effective and yields relatively long running times. The most commonly used solid lubricants are graphite and molybdenum disulphide. These solid lubricants are applied to the raceway surfaces in the form of powder loose, sliding lacquer or paste. Graphite and molybdenum disulphide lubricants can be used for high operating temperatures of up to 450 °C [4].

2. The most common causes of bearing failureIn practice, damage or failure of a bearing are often the result of several mechanisms operating simultaneously. The failure can result from improper assembly or maintenance or from faulty manufacture of the bearing or of its adjacent parts [3].

In some instances, failure is due to a design compromise made in the interests of economy or from unforeseen operating conditions. It is the complex combination of design, manufacture, assembly, operation and maintenance that often causes difficulty in establishing the primary cause of failure. Consideration of each feature is required for reliable determination of the cause of bearing failure. Since more than one process may cause similar effects to these surfaces, a simple description of the appearance is usually inadequate to determine the reason for the failure [7].

In the event of extensive damage to or catastrophic failure of the bearing, the evidence is likely to be lost and then it will be impossible to identify the primary cause of failure. In all cases, knowledge of the actual operating conditions of the assembly and the maintenance history is of the utmost importance. Typically, the causes of bearing failure can be classified in five groups and various sub-groups as shown in figure 1.

The evolution of tribological research during recent decades has led to a remarkable increase of new knowledge describing failure mechanisms [7]. The data from this research field show that improper lubrication is the most commonly cited cause of bearing failure and accounts approximately 80% of breakdowns [12] (figure 2). Naturally, these percentages may vary from application to application depending on operating conditions and maintenance practices.

The selection of adequate bearing lubricants is based on decisions around whether to choose oil or grease, and determining what kind of additive is required [1]. This decision depends on some factors, such as operating load, speed and temperature.

Lubrication is a key factor that can make or break bearing service life. Some researches in the bearing industry have stated that improper lubrication can account around 80% of bearing failures [8]. Failure can be the result of excessively long time lubrication without renewing, unsuitable lubrication and lubrication contamination [12].

The excessively long time lubrication without renewing and unsuitable lubrication of rolling bearings represent a large percentage of premature bearing failures (approximately 20% each), and in most cases they can be prevented [9]. Unsuitable lubricant is a lubricant that does not contain the right additives, does not have the proper viscosity, or may not be designed for use in such an application or temperature range [9].

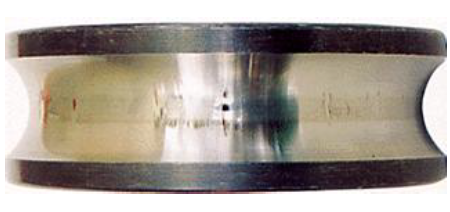

Abrasive wear can be the result of inadequate lubrication. The surfaces become dull to a degree that varies according to the coarseness and nature of the abrasive particles (figure 3). These particles gradually increase in number as material is worn away from the running surfaces and cage. Finally, the wear becomes an accelerating process that results in the failure of the bearing [7].

Improper lubricant viscosity is one the major causes of bearing failure. As for lubricating oils, viscosity is one of the most important properties and determines oil lubricating efficiency [8].

According to ISO 281:2007(E), the effectiveness of the lubricant is primarily determined by the degree of surface separation between the rolling contact surfaces. If an adequate lubricant separation film is to be formed, the lubricant must have a given minimum viscosity when the application has reached its operating temperature. The condition of the lubricant separation is described by the viscosity ratio, κ, as the ratio of the actual kinematic viscosity, v, to the reference kinematic viscosity, v1 (1) [6]:

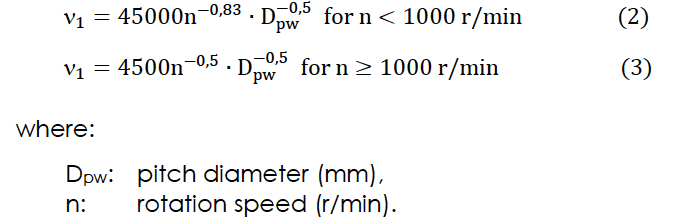

In order to form an adequate lubricant film between the rolling contact surfaces, the lubricant must retain a certain minimum viscosity while at operating temperature. The bearing life may be extended by increasing the operating viscosity, . The reference kinematic viscosity, 1, can be estimated by means of the diagram in figure 4, depending on bearing speed and pitch diameter, Dpw, or calculated with the equations (2) and (3) [6]:

In order to form an adequate lubricant film between the rolling contact surfaces, the lubricant must retain a certain minimum viscosity while at operating temperature. The bearing life may be extended by increasing the operating viscosity, . The reference kinematic viscosity, 1, can be estimated by means of the diagram in figure 4, depending on bearing speed and pitch diameter, Dpw, or calculated with the equations (2) and (3) [6]:

The calculation of κ is based on mineral oils and on bearing raceway surfaces machined with good manufacturing quality. The diagram in figure 4 and equations (2) and (3) can also be approximately used for synthetic oils like Synthetic Hhydrocarbon (SHC), for which the larger viscosity index (less change of viscosity with temperature) is compensated for by a larger pressure-viscosity coefficient for mineral oils, and by that about the same oil film is built up at different operating temperatures if both oil types have the same viscosity at 40 °C. The diagram in figure 4 and equations (2) and (3) apply equally to the base oil viscosity of greases. With grease lubrication, the contacts may operate in a severely starved condition because of the poor bleeding capability of the grease leading to poor lubrication and possible reduction of life [7].

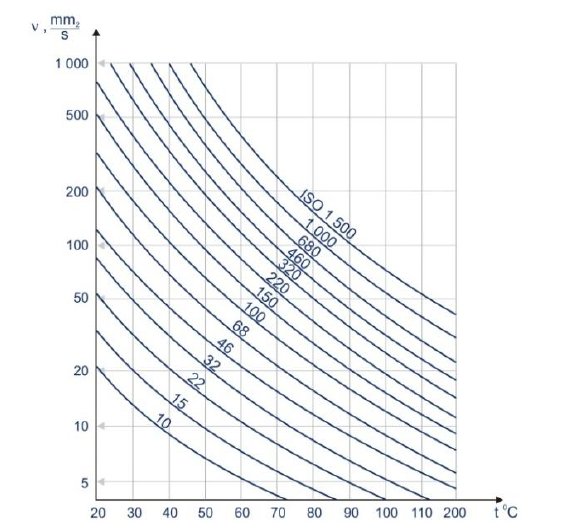

Oil kinematic viscosity depends on bearing operating temperature. Figure 5 represents oil kinematic viscosity- operating temperature comparison chart for the purpose of selecting lubrication oil with viscosity characteristics appropriate to an application.

The faster the flow, the lower the viscosity, and vice versa. If viscosity is too low, the oil film will not form, and damage will occur to the bearing contact surfaces. On the contrary, when viscosity is too high, viscous resistance will also be great and temperature due to friction will be high. In either case, the asperities (microscopic machined high points) of the bearing component surfaces may contact each other, initially causing a frosted or smearing condition, followed by adhesion at the contact points [9]. Failure of the bearing will be inevitable (figure 6).

Contamination from water, chemicals, and particles is especially harmful to rolling bearings and represent 25% of premature failures [14].

When the lubricant is contaminated with wear solid particles, permanent microcracks on the bearing raceway can be generated when these particles are over rolled. The appearance of these microcracks can generate local stresses, which will lead to a reduced life of the rolling bearing [7].

The life reduction caused by solid particles in the lubricant film is dependent on [6]:

1. type, size, hardness and quantity of particles;

2. lubricant film thickness;

3. bearing size.

In case of a viscosity ratio κ < 1 and a contamination factor eC for this viscosity ratio, a value of κ = 1 can be used in the calculation of the contamination factor, eC. For values of κ > 4, the value κ = 4 shall be used. The motivation for increasing the κ value is that a favorable smoothening effect of the contacting surfaces can be expected when an effective EP additive (Extreme Pressure additive) is used. In case of severe contamination (contamination factor eC < 0,2), the efficiency of the EP additives shall be proven under actual lubricant contamination. The efficiency of the EP additives should be proven in the actual application or in an appropriate bearing test [6].

The contamination factor, eC, is function of viscosity ratio, κ, and pitch diameter, Dpw [6]:

![]() When steel, used for rolling bearing components, is in contact with moisture, e.g. water or acid, oxidation of surfaces takes place. Subsequently the formation of corrosion pits occurs and finally flaking of the surface. A specific form of moisture corrosion can be observed in the contact areas between rolling elements and bearing rings, where the water content in the lubricant or the degraded lubricant reacts with the surfaces of the adjacent bearing elements [7] (figure 7).

When steel, used for rolling bearing components, is in contact with moisture, e.g. water or acid, oxidation of surfaces takes place. Subsequently the formation of corrosion pits occurs and finally flaking of the surface. A specific form of moisture corrosion can be observed in the contact areas between rolling elements and bearing rings, where the water content in the lubricant or the degraded lubricant reacts with the surfaces of the adjacent bearing elements [7] (figure 7).

Bearing contamination problems can be easily avoided if proper design and adequate maintenance of sealing and lubrication system are used.

Inadequate maintenance practices associated with misalignment and shaft tilting influence contamination related failures, due to large shaft orbits that develop. A major tendency of the inspectors that conduct the analyses of bearing failure is to jump to the conclusion that there is a sealing problem, when the damaged mechanism appears to be contaminated. Upon detailed examination, it is likely possible that the real problem is due to an excessive misalignment between components, which created the secondary seal problem. Solving the sealing problem will not solve the misalignment between components; in fact, the seal replacement may have a superior sealing capability but an even lower tolerance misalignment [3; 14].

Many bearings are simply brought to failure receiving insufficient lubricant quantity or no lubrication throughout their short life. Among others, the most common causes are simple neglect, incorrect lubrication intervals and failed lubrication system. For proper application, bearings must be monitored to ensure that lubricant intervals are not too frequent, causing overlubrication, and not too infrequent, causing underlubrication [13].

Smearing can occur on the guiding flange faces and on the ends of the rollers due to insufficient lubrication (figure 8). In full complement bearings (cageless), smearing can also occur in the contacts between rolling elements depending on lubrication and rotation conditions [7].

Overlubrication occurs when a rolling bearing is greased excessively or when too much oil is added to the housing. Excessive grease or oil quantity may cause internal friction between rolling parts, which generates excessive temperature that can create stress and deformity of the bearing [9].

Increasing the quantities of oil and grease in rolling bearings is not a good solution, since this practice may cause a churning action between rolling elements, and the result will always be an increase in temperature. Oil with high viscosity or grease with high consistency will also increase the temperature [2].

2.2. Inadequate bearing selectionUsually, the selection of bearing made by the original equipment manufacturer is the correct selection for the application. Of course there are some exceptions, and there is always the possibility that a wrong bearing is used for the application. This possibility should be considered after all other sources of failure have been investigated. If there are any changes in the working process, these may necessitate the possibility of using a new bearing, but not all the times this is a good solution [14].

Another common mistake is the use of a larger or stronger bearing, believing that this arrangement will increase radial load capacity. The larger or stronger bearing will not solve the true root cause problems. On the contrary, this new layout may create additional problems as, for instance, that the selected bearing may have a speed lower than the nominal one and may not work properly in a environment with relatively high trust. In some cases, bearings require to be preloaded to facilitate rolling motion and to prevent roller skidding. Replacing the original bearing with a new one may actually lead to failures that are more rapid if it is not properly loaded. As a general rule, for an industrial application the replacement of a bearing has to be done with the same type of bearing, selected by the original equipment manufacturer [5; 14].

Inadequate bearing selection represents about 10% of all premature bearing failures.

2.3. Improper mountingImproper mounting accounts for about 5% of all premature bearing failures. Improper installation can lead to bearing failure through load imbalance, misalignment or improper load distributions. A change of misalignment of 0,01/10 mm is enough to cause huge rise in vibration and temperature in the bearing. These sudden changes may introduce heavy wear in the ball or roller pockets where they run. These problems can be detected as a non-parallel running mark of the ball on the outer raceway and as means of extra wide ball or roller pathway on the inner raceway [11].

Improper mounting can also lead to failure due to excessive or uneven heating of the bearing, when this is mounted on a shaft or housing. When heat is required to expand an inner ring, the temperature must not exceed 125 °C. Besides, if for the mounting technique induction heaters are used, it is important to demagnetize the bearing before installation. In case of magnetization, the roller bearing may fail very quickly due to its attraction of ferrous metal particles (figure 9) [9].

Indirect failures, such as unacceptable operating conditions, transport, storage and handling represent 4% of premature bearing failures.

Among other indirect causes, the worst operating conditions are overloading, over-speeding, excessive vibrations, high temperature and electrical discharge [9].

“Overloading of a stationary bearing by static load or shock load leads to plastic deformation at the rolling element/raceway contacts, i.e. the formation of shallow depressions or flutes on the bearing raceways in positions corresponding to the pitch of the rolling elements” [7] (figure 10). Furthermore, overloading can occur by excessive preloading or incorrect handling during mounting [7].

If the typical bearing load and rated speed are doubled, then the bearing life may be reduced by up to respectively 90 and 50% [9].

Electrical discharge is becoming a serious problem for bearings. During equipment operations, V-belt drive systems may produce a high level of static electricity, that can be dissipated through the bearings to ground, causing pits or fluting to form on the bearing [9]. Initially the surface damage takes the shape of shallow craters, which are closely positioned to one another and small in size. This happens even if the intensity of the current is comparatively low. Flutes will develop from the craters in time, as shown in figure 11. They can be found on roller and ring raceway contact surfaces, but not on balls, which have dark coloration only [7].

Stray magnetic fields in electric motors, both AC and DC, can generate high electrical currents that will pass through bearing producing damages. To eliminate these problems, grounding brushes should be used [9].

Vibration represents a huge problem as for bearing failures. In fact, vibration in a bearing while stationary can cause damage, called false brinelling. The damages can be identified as bright polished depressions or reddish stain common to fretting. These marks left by false brinelling will be equal to the distance between the rolling elements, just as it is in the cases of true brinelling, so these two conditions are often difficult to be distinguished [9]( figure 12).

Higher temperatures than those recommended by the manufacturer represent a risk factor for bearing life, no matter what type, quality or amount of lubricant is used. To highlight the importance of this point, consider the fact that a good quality mineral oil begins to oxidize at 71 °C. The same result will occur in greases where such oils are used as the lubricating agent [9].

Handling starts when a rolling bearing leaves the factory to the point when it is installed on a machine, and continues if the machine is to be transported after it is installed. Proper transportation and storage are essential to prevent damages from occurring before the machine is even placed in service [9].

2.5. Material defects and manufacturing errorsThe ultimate failure causes for a bearing are material defects and manufacturing errors. Rolling bearing failures due to manufacturing defects make up less than one percent of overall bearing failures around the world. This percentage is being continuously reduced by improvements in manufacturing process and material technology. Today bearing manufacturers use sophisticated instruments to detect surface and subsurface bearing material defects, eliminating in this way poor quality products during the manufacturing process [9].

3. ConclusionsConsidering the facts mentioned above, the most common cause of bearing failure is lubrication, whether it is poor lubricant selection, poor application, lubricant contamination or lubricant degradation. It should be understood that proper and accurate lubrication offers cost saving opportunities, by eliminating not only catastrophic but also functional failures which impact production, and extends the life of many oil and grease wetted components.

References

[1] Banister K., Measure to Improve Bearing Lubrication, PEM-MAG Company, www.maintenanceworld.com.

[2] Conyers J., Bearing Failures, SKF Maintenance Institute. www.maintenanceworld.com. [3] Dale E. Stallard, Bearing Lubrication Under Extreme Conditions, Rexnord Bearing Products, 2008.

[4] FAG Bearing Corporation, Rolling Bearing Lubrication, Publication number WL81115/4EA, 2002.

[5] Fitch J., Silent Assumptions of Bearing Reliability, Practicing Oil Analysis Magazine. 2003.

[6] ISO 281:2007(E), Rolling Bearings-Dynamic Load Ratings and Rating Life.

[7] ISO 15243:2004(E), Rolling Bearings-Damage and Failure-Terms, Characteristics and Causes.

[8] Koyo Seiko Co. Ltd., Rolling Bearings: Failures, Causes and Countermeasures.

[9] Maintenance Technology International Inc., Troubleshooting Rolling Element Bearing Problems. Introduction to Bearing Failures.

[10] NTN Bearing Corporation, Care and Maintenance of Bearing, Catalogue no. 3017/E. [11] SKF Reliability Systems, Bearing Lubrication. An Introduction to Oil and Grease Lubrication of Rolling Elements Bearings.

[12] SKF Bearing Corporation, Bearing Failures and Their Causes.

[13] Bearings for High Temperatures http://www.maintenanceworld.com/Articles/powert ransmission/Bearings-for-High-Temperatures.html

[14] Uzaldin S. Abdul Hussain, ElKhawad A. Elfaki, Ibrahim A. Mohammed Ali, Causes and Remedies of Bearing Failure in Sudanese Industry, Department of Mechanical Engineering, Sudan University of Science and Technology.

Source: BearingNEWS magazine March Issue