Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

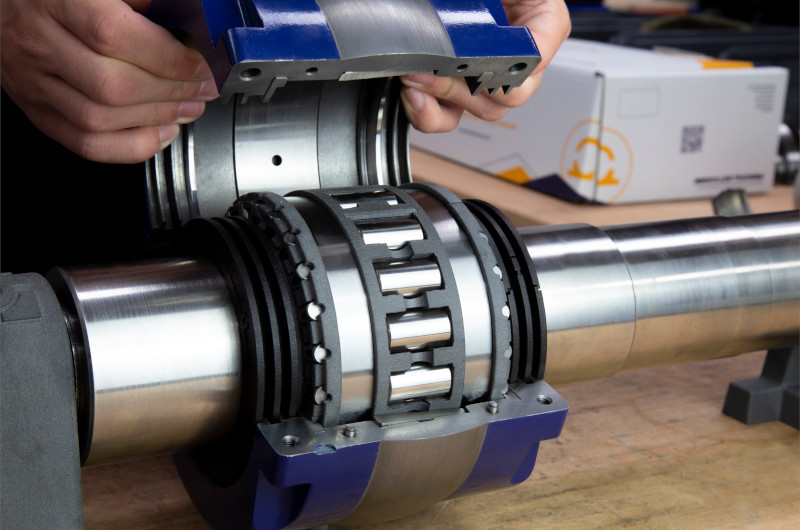

TECHNOLOGYGlobal bearings innovator, Bowman International, has launched to market a split roller bearing with substantially higher radial and axial load capacities.

Ideal for applications such as propulsion shafts in ships, screw conveyors in abrasive industrial environments and conveyor drives in the mining sector, the new Bowman Advanced Split Roller Bearing offers up to 75% higher radial load capacity and up to a 1000% increase in axial load capacity in both directions.

Ian Breeze, Technical Director for Bowman, comments on the significance of this innovation:

Ian Breeze, Technical Director for Bowman, comments on the significance of this innovation:

“For the first time, plant manufacturers and maintenance engineers across all heavy-side sectors can specify a split roller bearing that does not rely on race lips alone to accommodate axial force in high-load applications. The new Bowman Advanced Split Roller Bearing comprises two independent 3D-printed axial bearings designed to accommodate greater loads, improving system performance with less maintenance and reduced unplanned machine failure. In fact, compared to other market-leading split bearings, the Bowman Advanced Split Roller Bearing increases bearing L10 life by up to 500 per cent.”

Meeting the bearing demands of modern industryTime and cost pressures affect all sectors and for industrial applications, the need to produce more, faster, takes its toll on machinery, meaning components must be able to withstand the additional load.

For decades, the split roller bearing market has stood still, unable to accommodate the evolving needs of these vital high-load applications, resulting in more maintenance, expensive downtime and lost production capacity.

This is a challenge Bowman tackled head on and now, thanks to the technological possibilities of 3D printing, there is a split roller bearing with enough thrust capacity and increased radial load capacity to replace solid spherical roller bearings in rotating machinery. The resulting reduction in downtime, quicker maintenance processes and improved machine performance all translate to cost and time efficiencies.

Up to ten times faster bearing changes

Up to ten times faster bearing changes

Delivering up to ten times faster bearing change times compared to solid bearings, Bowman Advanced Split Roller Bearings have been designed with speed of maintenance in mind.

“When space is limited, engineers often need to disconnect the coupling and move other equipment, such as motors, gearboxes or pumps out of the way before they can slide solid bearings off the shaft for replacement or maintenance,” explains Ian.

“Split roller bearings can be assembled radially around the shaft, eliminating these additional logistical challenges and making maintenance and replacement a lot faster and more cost-effective. To further enhance time and cost savings, the Bowman Advanced Split Roller Bearing uses the rollers to lock the two cage halves together, eradicating the use of small and easy to lose clips and other locking components.”

Compatible with existing competitor housings

Compatible with existing competitor housings

As part of the Advanced Split Roller Bearing portfolio, Bowman has created a range of dimensionally interchangeable retrofit products that can be fitted directly into the existing competitors bearing housings to quickly and cost-effectively improve radial and axial load capacities.

These Interchangeable Split Roller Bearings have been designed with equivalent critical mounting dimensions to all other leading bearing brands, so that they can slot directly into other manufacturer’s cartridges for instant performance improvements.

In fact, retrofitting existing bearings, but keeping the housing in-situ can exceed the capacities offered by the current market leader by up to 26 percent, resulting in up to double the bearing L10 life, reduced downtime and increased productivity.

The Interchangeable Split Roller Bearings are available in 01/01E/Light series from 30mm to 300mm and 02/02E/Medium series from 190mm to 300mm shaft sizes.

A benefit-rich split roller bearing designed to performFurther enhancing the performance of this revolutionary split roller bearing is a patented triple labyrinth seal which not only offers a tighter seal than other split bearings, but also reduces the need for costly removal, machining or replacement of worn shafts.

When a shaft becomes worn, engineers can simply fit a new extended seal covering the undamaged part of the shaft, without compromising performance and without the need for extended downtime.

Alongside the significant increase in radial and axial load capacity, this new bearing design offers a range of additional installation and performance benefits, such as larger diameter screw sizes to accommodate increased capabilities for the clamp rings, cartridges and pedestals and roller pockets with cavities to hold the grease against the rollers.

Connectivity and data-driven performance analysisTo support the smart factory evolution and the integration of connectivity into industrial environments, Bowman offer the addition of temperature and vibration monitoring sensors that can gather data in real-time and alert maintenance engineers of pending machine failure.

Real-time monitoring of bearing conditions can assist with predictive maintenance and reducing downtime, alerting the engineer via smartphone or the site’s building management system.

Bespoke adaptations within short lead timesHigh-load applications often operate in abrasive, unpredictable or complex conditions, and asset owners may require special bearing adaptations in order to optimize the performance of their system.

With inhouse 3D printing capabilities and a team of dedicated innovators, Bowman can offer a full consultation and design service to create bespoke adaptations deliverable within short lead times.

Ian adds: “We have the facilities and the technical design skill to understand any non-standard bearing application quickly and respond to customer needs with innovative, durable and cost-effective solutions. For the heavy-side industries, bearings are not always an off-the-shelf purchase and Bowman prides itself on being the manufacturer of choice, not just for straight-forward, high-volume installations, but for more complex and niche product requirements too.”

Optimised performance at a market-leading price pointWhen designing the Advanced Split Roller Bearings, Bowman strived to create a product that surpassed all performance boundaries in the split bearing market at a price point that was competitive for OEMs and end users.

Ian concludes: “Bowman is a proud innovator of bearing solutions that solve real industry issues. We are the first manufacturer to create a split roller bearing capable of increasing the lifespan and performance of high-axial load systems and thanks to the production benefits of 3D printing, we have been able to deliver this product to market at a price point up to 20 per cent lower than other leading split bearings. These cost savings were something we were keen to pass on to customers.”

For more information on the Bowman new Advanced Split Roller Bearing, visit www.bowmansplitbearings.com.