Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGY

Analysis of the wind gearbox repair process

A gear transmission (gearbox) is one of the most important components of wind turbines. It is an element of the system intended for converting the kinetic energy of the wind into electric power. The history of the creation of gears being the key structural element of the gearbox, dates back many hundreds of years before the Common Era. Initially, these historical gear solutions were made of wood. Despite many centuries of this technology development, gears and other industrial devices are not failure-free. It is due to various technological, dimensional and, above all, economic constraints. The following considerations are based on a case study of damage, inspection, overhaul and tests of a gear transmission (gearbox) used in onshore wind power plants with a capacity of less than 2.5MW.

Gearboxes used in wind power plants are usually designed for 20 years of operation, but the real period of failure-free operation is usually 10 years. The gearbox damage/failure may result in long downtime and a consequent lack of revenues generated by the wind turbine. Some failures can be remedied without removing the gearbox from the nacelle. These are including but not limited to the replacement of bearings or a complete HSS shaft. According to Shawn Sheng (NREL 2014), more than 50% of failure cases are related to the HSS shaft bearing. More extensive failures resulting from damage to the teeth of cylindrical and planetary stages concern about 28% of cases. In the event of broken teeth, it is usually necessary to remove the gear from the nacelle and replace it with a fully operational one. In the case of limited availability and long delivery times for new gearboxes, the only way to restore the full operationality of the turbine is to carry out a comprehensive overhaul of the damaged gearbox.

Typical environmental causes of damage to gearboxes are extreme wind conditions and their variability, wide range of ambient temperature, corrosive environment (especially for offshore power plants) and pollution. The technological process, and particularly its repeatability, assembly/installation correctness and transport conditions are the quality parameters influencing the reliability of the gearbox operation. The third group of factors are operation and maintenance conditions. The key issue is to verify the oil cleanliness and degradation and to predict the occurrence of emergency conditions by using the CMS online systems.

The CMS systems monitor the loads and rotational speeds of the gears, vibration levels, bearing and oil temperatures, oil flows in the forced lubrication system and the contamination level of filter cartridges. There are systems where the increase in the amount of solid particles or the water content in oil is monitored by means of speciality transducers.

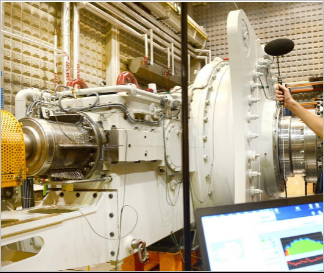

If any symptoms of damage are detected (increased vibration levels, increased content of metallic parts in oil, increased bearing or oil temperatures), a direct visual inspection of the gearbox condition is performed. The main technique applied in such a case is a visual analysis of the damage by means of an endoscopic camera. The person conducting the inspection may be additionally supported by using the AR glasses (Fig. 1), enabling remote consultations with specialists located in the local service centre or in the engineering department.

When a damage is found, it is necessary to make decisions that will have the least impact on reducing the turbine downtime. Lack of planning in this area most often leads to large financial losses due to the lack of availability of logistic means allowing for the removal of the gearbox from the nacelle and its replacement with an operational one. In such situations and in the current market situation, downtimes may exceed many months (this applies to the wind energy market in the EU).

The gearbox repair should start with a comprehensive visual inspection. This is intended to estimate the location and the extent of damage. While disassembling the gearbox the situations may occur where, due to teeth fracture and deformation, the mating parts are seized (Fig. 2).

In such cases, despite the damage to the toothed wheels, it is necessary to dismantle them in order to recover the planetary stage carrier. Due to the dimensions, fits and masses of the elements to be dismantled, experience and the use of appropriate equipment are of crucial importance. Experience shows that the most destructive damages are associated with failures on the planetary stages. The meshing of the planetary stage is the most strenuous, and the bidirectional bending of the planetary gear teeth intensifies the fatigue phenomena resulting in damage.

After complete disassembly of the gearbox and cleaning of the details, the technical condition is assessed. It is carried out in order to select components to be re-used and to specify the cause of failure.

Visual assessment of the toothed elements allows the following damages to be detected:

• fractures and cracks of teeth (Fig. 3),

• macroscale plastic deformation of teeth,

• scuffing,

• pitting,

• overheating,

• fretting corrosion (fig. 4),

• indentations etc.

In the case of visual analysis of the bearings, it is possible to identify damages such as:

• Flaking, peeling,

• Scoring,

• Smearing,

• Fracture,

• Cracking,

• Cage damage,

• Indentations (Fig. 5),

• Pitting,

• Fretting,

• False brinelling,

• creep,

• mounting flaws,

• seizure etc.

In addition to the visual assessment, measurements of toothed elements should be carried out with the use of coordinate machines (Fig. 6). This allows the wear and deformation of the tooth line, profile and pitch to be assessed. Based on the measurement results, a decision can be made whether the undamaged gears should be put back into operation.

Cracking on the tooth surface is detected by magnetic particle inspection (Fig. 7).

The final inspection step is the body and carrier measurements. They should be carried out in order to confirm the geometrical conditions, wear of bearing seats and the position of the gear axles.

The inspection report is the basis for making arrangements with the client regarding the scope of the overhaul.

The overhaul procedure includes:

• replacement of bearings,

• recovery of the planetary stage and cylindrical stage gears including the teeth microgeometry optimization,

• Regeneration of the planetary stage carrier,

• Regeneration of the gearbox body,

• regeneration of bearing seats on shafts.

While repairing the wind gearboxes, it is necessary to recover the damaged gears of the planetary stage or cylindrical stage. As part of these activities, it is necessary to develop a project of adaptation of a new gear node to the existing installation conditions (axis distances, gearbox stage ratios). This procedure is often aimed at optimizing the structure on a microgeometry level by selecting the tooth line modification or the tooth profile (taking into account the body and shaft deformations) in order to improve the conditions of meshing interaction, to equalize stress levels and to minimize the sound intensity level. After the manufacturing documentation has been developed, the production process is carried out (Fig. 8). It is important that the toothing tolerance class ensures uniform/even load and low vibration levels resulting in the noise level emitted by the gearbox and its durability. Ensuring high-quality work and durability of the planetary stage, apart from the technical aspects described above, is achieved by appropriate grouping of planetary gears in relation to the parameter decisive for the uniformity of the teeth load.

An important phase related to the gearbox overhaul is its reassembly. Errors associated with incorrect mounting of the bearings may prove to be particularly costly. This applies both to situations where, during the assembly works, mechanical damage to the raceway or rolling components occurs, as well as the selection of incorrect settings of the systems when using tapered roller bearings.