Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGY

Abstract: In today’s rolling bearing industry, the demand for more and more reliable and effective products is continuous. For standard operating conditions the rating lives of bearings, with ideal internal geometries and correct mounting, are ultimately established by the quality of the steels used in the manufacturing process. For this reason, the RKB Group has undertaken extensive researches and has made great strides in the field of bearing materials and heat treatments. Our long-standing cooperation with the top-class steel manufacturers has given RKB Bearing Industries a unique understanding of material development for rolling bearings. The present paper presents an overview of the importance of the proper selection of the bearing steel for manufacturing high quality rolling bearings, according to the highest international standards. In addition, the complex interrelation between steel cleanliness and adequate heat and thermo-chemical treatments applied to bearing components is pointed out. The equilibrium between these factors has led to an increased fatigue life of the rolling bearings manufactured by RKB.

Key words: Bearing steel, cleanliness, fatigue life, heat treatment, metallography, non-metallic inclusions

Rolling bearings are one of the most frequent machine elements and play a key role in the reliability of the majority of industrial equipment. In this respect, the selection of the proper bearing material and its processing are of the utmost importance.

Over the years, the specific requirements of rolling bearings, i.e. rolling contact fatigue strength, resistance to contact deformation and wear, toughness, machinability and hardenability, conducted to a special grade steel commonly known as bearing steel [1].

There are two major rolling bearing steel variants [2]:

– the through-hardened steels (table 1), for which, after the final heat treatment, the hardness attains the high value of 58-64 HRC in the entire volume if the bearing components;

– the through-hardened steels (table 1), for which, after the final heat treatment, the hardness attains the high value of 58-64 HRC in the entire volume if the bearing components;

– the case-hardened steels (table 2),for which a carburizing treatment increases the carbon content up to 0.65-1.10 % only in a superficial layer of 0.7-3.5 mm thickness, where a proper hardening and tempering treatment ensures the needed high hardness of 58-64 HRC,while maintains the rest of the material at a much lower hardness 0f 32-48 HRC that provides a better operating toughness.

The appropriate steel selection for the manufacture of rolling bearings is based on the particular bearing industrial application, geometry, size, production technologies and associated costs [1].

One major factor that determines the rolling bearing fatigue life is the homogeneity and purity or cleanliness of the steel. A given steel can be considered clean if its content of impurities, such as phosphorous, sulphur, silicon and aluminum, is very low. These impurities in combination with oxygen form non-metallic inclusions [4].

If two groups of identical rolling bearings were manufactured using the same type of materials, but from different lots, which means possible different contents of non-metallic inclusions, a considerable difference in the distribution of the actual fatigue lives might be expected [5]. The existing non-metallic inclusions act as stress risers able to initiate micro-cracks during the repeated contact stresses introduced by the rolling load in the shallow layer of the raceways. Eventually these micro-cracks can break through the raceway surface and in time spalling may occur and lead to total bearing failure (figure 1) [6].

If two groups of identical rolling bearings were manufactured using the same type of materials, but from different lots, which means possible different contents of non-metallic inclusions, a considerable difference in the distribution of the actual fatigue lives might be expected [5]. The existing non-metallic inclusions act as stress risers able to initiate micro-cracks during the repeated contact stresses introduced by the rolling load in the shallow layer of the raceways. Eventually these micro-cracks can break through the raceway surface and in time spalling may occur and lead to total bearing failure (figure 1) [6].

To obtain an appropriate cleanliness grade it is necessary to control and improve a wide range of operating practices during the steel manufacturing process, like deoxidant and allow additions, secondary metallurgical treatments and casting activities [3].

As already pointed out, steel cleanliness plays a crucial role in the development of high quality bearings with superior operating performances.

In the regard, to ensure the required hardness, high resistance to contact deformation and wear, and good dimensional stability, RKB bearings are primarily made of SAE 52100 through-hardened high carbon chromium steel as presented in table 1. In order to guarantee the premium quality of its products, the RKB Group regularly and carefully checks the steel chemical composition, especially the upper limits of oxygen content (table 3).

For bearings with large cross-sectional dimensions the SAE 52100/A steel is used to improve the hardenability, having higher contents of manganese, silicon and chromium. SAE 52100/A steel is similar to 100CrMnSi6-4 or GCr15SiMn steels [7] and features a reduced number of elongated sulphides.

For special industrial applications, the RKB Group can use SAE 9315 case-hardened steel, which is a nickel-chrome-molybdenum steel (table 2) [7].

The RKB case-hardened steels, carburized to the proper depth and surface hardness of 58-64 HRC, have a softer (32-48 HRC), energy-absorbing core that in case of shock loads provides performances better than those given by through-hardened bearing steels [2].

Both RKB through-hardened and case-hardened steels are produced in bars through a series of processes:

electric furnace melting furnace refining and degassing continuous casting heating and refining hot rolling/forging and annealing.To find out material defects before the manufacturing process starts, steel bars are randomly subjected to nondestructive tests, the ultrasonic method being the most used.

The latest achievement of the RKB Group and its steel supplier in this field is represented by a new and improved version of through-hardened steel called RKB Type. RAV Protocol, which has a chemical composition similar to SAE A485 steel. This innovative protocol is particularly suitable for manufacturing rolling bearings in the RKB Victory Line class.

To respect the limits imposed by the latest international standards in terms of non-metallic inclusions, that is cleanliness, the RKB Type.RAV steel is subjected to a rigorous purification process called Vacuum Degassed Electroslag Remelting or VAC-ESR (figure 2).

The VAC-ESR process gives major advantages in terms of steel macro and microstructure, which results in both improved product reliability and reduced needs for maintenance. These advantages are related to [1]:

deep desulfurization, refining and homogeneous distribution of non- metallic inclusions, fine grain structure, no shrinkage defects and macro-segregation.As shown in figure 3, the benefits offered by the RKB Type.RAV steel to our bearings are evident in terms of heat treatments, fine grinding and inspection processes, wear and corrosion resistance, easy mounting process, basic rating life and life cycle costs (figure 3).

2.1 Heat treatments benefits

Having a proper chemical composition and fine grain structure, the RKB Type.RAV steel capitalizes on special heat treatments to reach a proper hardness of 58-64 HRC, uniform throughout the section area of the bearing components.

2.2 Fine grinding benefits

The higher content of non-metallic inclusions of SAE 52100 standard steel manifests firstly as a disadvantage during the fine grinding process, when the softer steel matrix surrounding the hard brittle non-metallic inclusions is partly removed. The removal of the inclusions from the steel surface forms voids or pits (figure 4). Furthermore, during bearing running, these voids can react as micro- crack initiators that finally may lead to the total bearing failure. On the contrary, the RKB Type.RAV steel, thanks to its high cleanliness rate remarkably, decreases the probability to produce such cavities.

2.3 Wear resistance benefits

The specific structure of the RKB Type.RAV gets any bearing damage spread four times slower than in bearings made of standard steel.

Our bearings made of RKB Type.RAV steel are less susceptible to contaminants, meaning that the indentations caused by foreign solid particles will not cause premature fatigue damages.

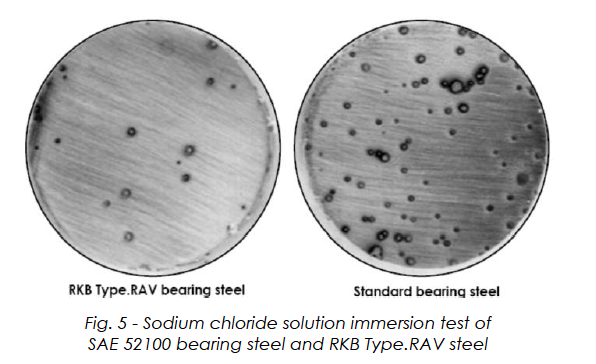

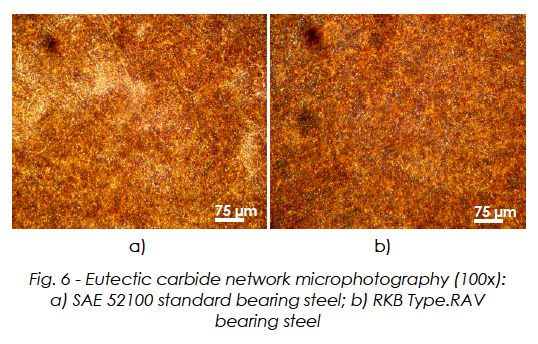

The high corrosion resistance of the RKB Type.RAV steel was proved in a sodium chloride solution immersion test (figure 5). As it can be easily noticed, there is excessive rust on the SAE 52100 standard bearing steel surface compared with the RKB Type.RAV steel sample. In fact, standard bearing steel contains coarse eutectic carbides that act as crack initiators and reduce chromium content in the martensitic matrix (figure 6a).

Conversely, the RKB Type.RAV steel has no eutectic carbides but consists of fine dispersed carbides and strong martensite that improve resistance to corrosion (figure 6b).

2.4 Mounting process benefits

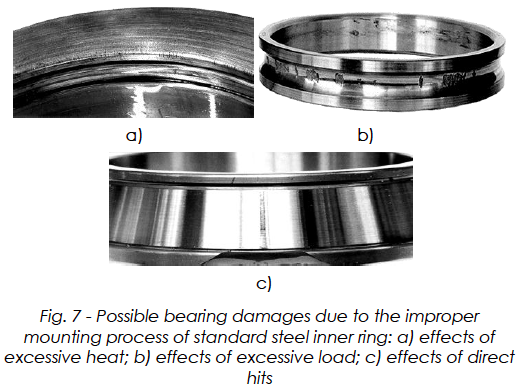

As common knowledge, an improper mounting process can damage the rolling bearing (figure 7) [8]. Due to the more stable structure of the RKB Type.RAV steel, the possible overheat generated during an improper mounting operation does not affect the involved bearing elements.

The RKB Type.RAV steel has a finer grain size which increases material strength and its ability to take heavy loads and shocks. Additionally, the higher toughness of the RKB special bearing steel protects the bearing components from being damaged by the direct strokes that might appear during an inadequate mounting process.

2.5 Rating life benefits

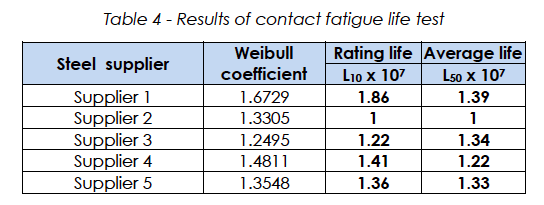

A contact fatigue life test was performed to check the quality of the bearing steel used by RKB in comparison with the steels provided by different producers. Five leading steel suppliers were selected and to one of them we imposed to respect the RKB JX80X Series bearing steel protocol for premium reliability in critical applications. The material test specimens were annealed and manufactured as washers, hardened in a gas protected electro furnace between 835 and 845 °C and finally tempered between 150 and 160 °C for 3 hours.

The evaluation was performed in a Test Life Prediction tester with a maximum contact stress of 4508 MPa and 2040 rpm. Each of the five testing groups contained a number of 16 test specimens. For each group, the tests were conducted up to the fatigue failure of all the specimens of the group.

The RKB Type.RAV premium class bearing steel, in compliance with our high quality standards, proved to be superior to the other materials.

The statistical values listed in table 4 and depicted in figure 8 point out that the test specimens made of our steel have the highest values for both rating and average life.

2.6 Life cycle costs benefits

At RKB, by means of our Type.RAV special bearing steel, we are pursuing the goal of developing individual problem solutions for customers in a large variety of applications, especially where the previously used rolling bearing materials have reached their limits, standard bearings must be replaced quite frequently and the downtimes of entire systems, including the cost system, are to be reduced. As Comparing the investment and capital costs for RKB bearings and standard bearings, our costs are a little bit higher (figure 9). However, these costs are quite soon recovered in terms of operating and maintenance costs. Therefore, thanks to the reliability of our bearings, ensured by the cleanliness and manufacturing quality of our steel, our clients get an economic profit.

As common knowledge, heat treatments for rolling bearings alternate heating and cooling operations under controlled atmospheric conditions to impart the desired material characteristics such as hardness, high tensile strength, improved machinability, proper grain size, and reduced residual stress. The thermal cycles that produce these specific material properties include the phases of annealing, carburizing (for case-hardened steels only), hardening, tempering and stress relieving (additional tempering) [1; 2].

Besides these conventional treatments, RKB can perform two additional heat treatments:

Bainitic Treatment (HB), and Dimensional Stabilization Treatment (S1, S2, S3, S4).The flowchart of the mentioned heat treatments is depicted in figure 10.

The RKB Bainite Treatment can be applied to bearing rings made of SAE 52100 steel, if they don’t exceed 17 mm thickness. RKB can apply HB treatment to inner ring (RKB HB3), outer ring (RKB HB 2) or both rings (RKB HB1).

The RKB HB3 or RKB HB2 heat treatments are carried out when the technical application requires a mounting process with high interference fit between the inner/outer ring and the shaft/housing. These heat treatments significantly reduce the internal stresses generated by the previous thermal cycles, that, in conjunction with an excessive interference fit, might cause inner/outer ring to crack.

The RKB HB1 heat treatment is selected when the technical application needs a simultaneously high interference fit between the inner ring and the shaft and the outer ring and the housing. By reducing the stress level the cracking incidence is reduced in both rings and a longer fatigue life is attained.

In addition, if the thickness of rings does not exceed 17 mm, also the RKB Dimensional Stabilization Treatment can be applied to both bearing rings made of SAE 52100 steel. RKB has the ability to conduct the Dimensional Stabilization Treatment for operating temperatures up to

350 °C, corresponding to RKB S4. However, the higher the dimensional stability, the lower the hardness, with negative consequences on bearing service life.

For ring thickness above 17 mm, the RKB Dimensional Stabilization Treatment cannot be properly applied to the entire material volume, while the RKB Bainite Treatment can be correctly performed.

Moreover, if rings are thicker than 17 mm, SAE 52100/A steel can be used for RKB bearings. In this case, the RKB Bainite Treatments cannot be applied to the bearing rings, due to the high content of silicon and manganese, that would increase the hardness and reduce the toughness outside the acceptable limits. By contrast, all RKB Dimensional Stabilization Treatments can be accurately applied to the bearing rings made of SAE 52100/A.

For critical/severe applications, the RKB Group uses SAE A485.RAV or RKB Type.RAV steel with both special heat treatments, independently of ring thickness.

Furthermore, the RKB Group can apply to its products two special thermo-chemical treatments:

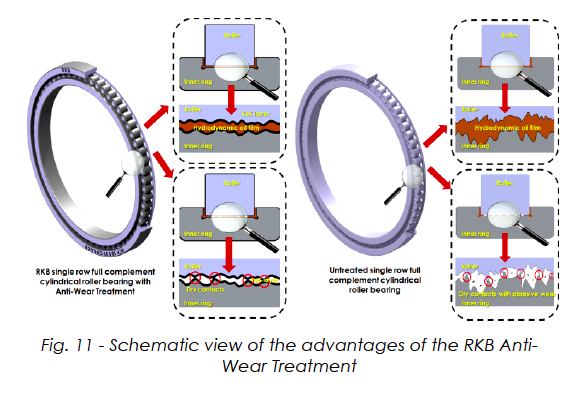

Anti-Wear Treatment (AWT), and Phosphate Treatment (PT).The RKB Group uses the Anti-Wear treatment to reduce both the friction and wear of the contacting surfaces that operate in mixed or even boundary lubrication regimes. The Anti-Wear treatment diminishes the risk of premature bearing failure and extends bearing service life.

The iron sulfide layer with a thickness of 3-6 µm, due to the Anti-Wear treatment, is as a porous and loose substance that absorbs more lubricating oil. It ensures the presence of a lubricating film between rolling elements and raceways, thereby diminishing both friction and wear of the contacting surfaces (figure 11). As a consequence of excessive loads or high accelerations and decelerations, the elasto- hydrodynamic film can be broken but, thanks to the self- lubricating layer of iron sulfide, the bearings with the RKB Anti-Wear Treatment can correctly function in the boundary lubrication mode without any abrasive wear.

On the contrary, in case of bearings without anti-wear treatment, the boundary lubrication regime implies an increased friction and, even more important thing, an intensive abrasive wear able to speed up the bearing failure.

The Phosphate Treatment is a thermo-chemical treatment used by RKB Bearing Industries to protect against corrosion the rolling bearings designed to work in corrosive environments. The Phosphate Treatment can be applied on both bearing rings (PT1), only on outer rings (PT2), inner rings (PT3) or on both bearing rings and rolling elements (PT4).

The RKB Group is committed to continuously improving its knowledge on bearing steel through the scientific research carried out by its Technical Department. The unceasing collaboration between the RKB Group and its steel supplier has allowed our through-hardened and case-hardened steels to have a further decrease in the content of oxygen and non-metallic inclusions, ensuring high cleanliness and a better rolling contact fatigue resistance.

The quality control performed by RKB on its steel and final products takes place on a multilevel basis by means of non-destructive tests, chemical composition controls, macro and micro-structure evaluations, mechanical properties measurements and final report for traceability (figure 12).

One of the most important tasks that the RKB Quality Control Department has to fulfill is to correctly quantify the steel cleanliness. To this end, the blue fracture test is used for the macro-inclusions evaluation, while the optical microscopy method is involved for the micro- inclusions evaluation. These methods permit a volumetric evaluation and give statistically significant numbers of the inclusions.

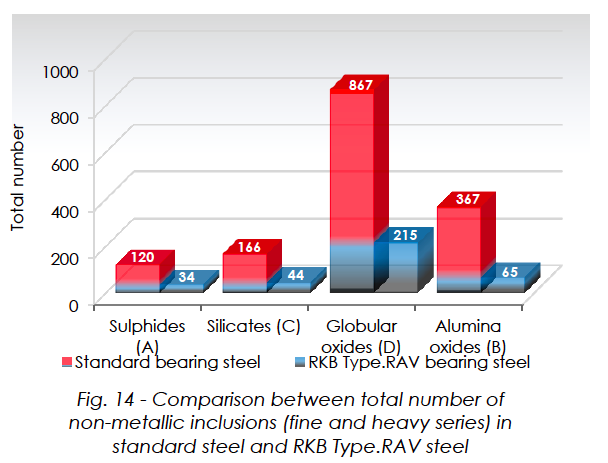

In order to make clear the differences between standard bearing steel and RKB Type.RAV special bearing steel, we evaluated them from a metallographic point of view. We investigated an area of approximately 112 mm2 for non-metallic inclusions according to ASTM E3 and ASTM E45

Figure 14 shows that the number of sulphides, silicates, globular oxides and alumina oxides, in fine and heavy series, is much higher in standard bearing steel than in RKB special bearing steel. The evaluation of the total length of non-metallic inclusions consisted in a longitudinal (parallel with the material flow lines) section inspection. As figure 15 points out the total length turns out to be much higher in standard steel than in RKB Type.RAV steel.

The rating lives of bearings with ideal internal geometries, correct mounting and standard operating conditions are ultimately established by the quality of the steels used in the manufacturing process.

To fulfill the requirements of the latest international standards in this field, the RKB Group has permanently undertaken incessant R&D activities on the quality of rolling bearing steel, particularly in terms of cleanliness, heat and chemical treatments and related process controls. The equilibrium between these factors has led to an increased fatigue life of the rolling bearings manufactured by RKB. For our customers, the result of these efforts is represented by more reliable rolling bearings with superior functional performances and longer lives.