Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

GWJ Technology GmbH, a calculation specialist from Braunschweig, Germany, added new functions to the gear modules of its eAssistant web-based calculation software, which has been successful for more than 20 years.

In the latest versions of the "Cylindrical gear pair" and "Planetary gear stage" calculation modules, the old DIN 3961 from 1953 for gear tolerances and tooth space allowances, which has been withdrawn for many years, has been integrated in response to numerous user requests. This makes it much easier for users to recalculate cylindrical gears on the basis of old drawings and is particularly helpful when manufacturing spare parts or updating drawings. In addition to DIN 3961:1953, the tolerance standards DIN 3961, DIN 58405, ISO 1328 and ANSI/AGMA 2015 are available for the calculation of cylindrical gears. Furthermore, the number of decimal places for the input fields can now also be individually configured in the "Cylindrical gear pair" and "Planetary gear stage" modules. For the design dimensioning available in both modules, further options for variant calculation have been implemented, such as "Allow specific sliding > 3" or "Allow small geometry errors".

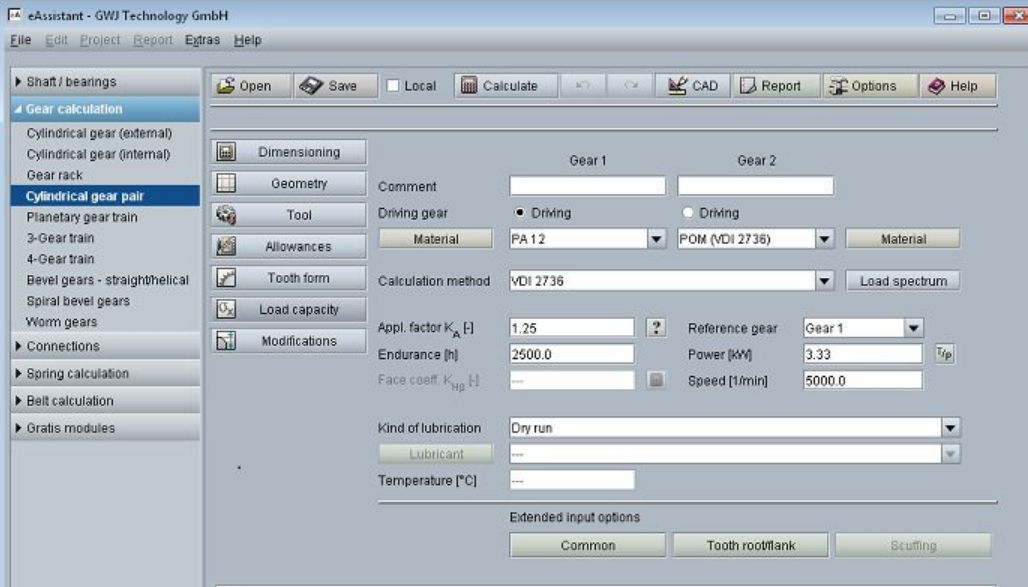

Furthermore, the eAssistant module "Cylindrical gear pair" now allows the calculation of the wear load capacity according to VDI 2736 for dry-running plastic/plastic or plastic/metal pairings. In the load capacity calculation according to DIN 3990, method B or ISO 6336, method B, the individual specification of further factors, such as roughness, lubricant, speed or size factor, is now possible.

With the ISO/TR 6336-30 published in December 2022, eight practical examples for the current ISO 6336:2019 are now available. GWJ uses these examples to verify its calculation modules, which include ISO 6336 or DIN 3990. The comparative calculations carried out in the meantime matched very well with the practical examples of ISO/TR 6336-30. For all 8 examples, the absolute deviation in the calculated safeties is ≤ 0.01.