Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

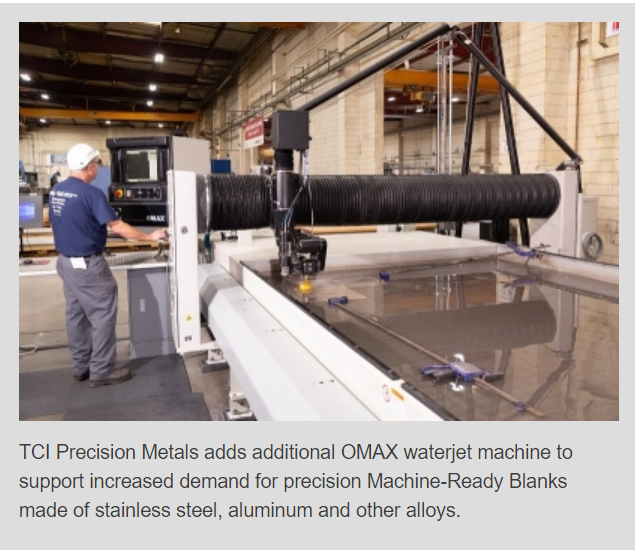

TCI Precision Metals has announced the installation of its second OMAX 80X waterjet machining center. The new machine is the second waterjet added in the last twelve months to keep up with growing demand for precision Machine-Ready Blanks and other specialty parts.

TCI has standardized on the OMAX 80X for its speed and more accuracy compared to other abrasive jet waterjets in the industry, which will help TCI Precision Metals maintain its excellent customer lead times even the face of growing demand.

“Our recent investments in both sawing and waterjet cutting equipment have paid off big for our customers by helping us shorten lead time and improve on time delivery. Most of our Machine-Ready Blanks orders are for either aluminum or stainless steel alloys. For our aluminum customers we previously installed a new Schelling fm8 plate saw, capable of cutting aluminum and other nonferrous metals up to 6-inches in thickness at speeds up to 100 ft/min. We then added our initial OMAX waterjet machine, and now our second one, capable of cutting stainless steel alloys and other ferrous materials that are up to 8″ thick on 15’0″ x 7’5″ table. This allows us to maintain complete control over managing our customer’s expectations when it comes to special needs and on time delivery,” said Ben Belzer, president of TCI Precision Metals.

OMAX waterjet machining centers are recognized as being highly accurate, flexible, and efficient. With its Tilt-A-Jet cutting head technology, the model 80X produces high precision, finished edge cuts that are square, with no edge tapper, which is a problem with many other waterjet matching centers.