Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

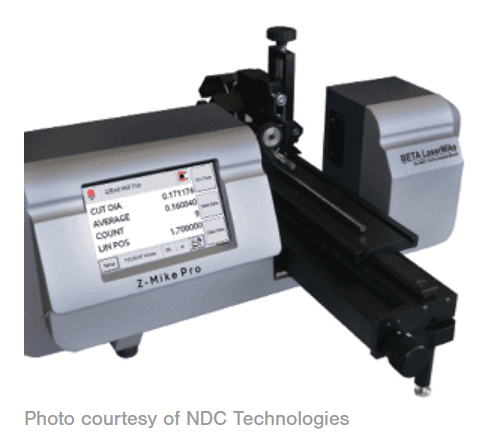

Z-Mike Pro provides absolute accuracy, reliability, and repeatability for dimensional measurements of O.D., ovality, taper, total indicated runout (TIR), and effective cutting diameter. The laser micrometer provides ±0.5µm accuracy and ±0.13µm repeatability offering versatility across a range of demanding measurement applications.

It’s available in two models to measure products up to 50mm. Ready-to-mount modular fixtures – from simple manual fixtures to fully automated and intelligent fixtures – to properly hold workpieces.

NDC Technologies

Benefits

No recalibration

Precision across entire measurement range

No need to center the object being measured

Measurements traceable to national standards

Turning grade for medium, high carbon steel

The AC8020P turning grade is for high efficiency turning of hard steel (~1030) and medium and high carbon steel (alloy steel, 1053, 4140, 4137 and bearing steel 52100). The grade fully complements the existing AC8000P series grades (AC8015P, AC8025P, and AC8035P) turning solutions for machining steel.

Increased strength of the alumina (Al2O3) layer delivers enhanced chip control while the golden surface color offers improved wear visibility. AC8020P has shown results of more than 2.5x chipping resistance versus conventional grades.

The EGU chipbreaker is recommended first and increases cutting speeds. The EGE chipbreaker is for applications requiring increased feed rates.

Steel turning grades in AC8000P series:

AC8015P grade (high speed grade) – light silver

AC8020P grade (for high efficiency) – gold

AC8025P grade (general purpose) – bright polish

AC8035P grade (interrupted machining) – dull silver

Automatic conveyor belt adjustment

The Auto-Take Up system conveyor enhancement eliminates the need for manual adjustments.

To prevent maintenance concerns or belt failures, the system automatically monitors tension using load cells on chain conveyors, including steel belt conveyors, drag conveyors, ScrapVeyor, and more. The system is wired to a programmable logic controller (PLC) which monitors tension and automatically tightens the belt to eliminate manual adjustments and downtime. It can be added to new conveyors or retrofitted onto existing models. If retrofitted onto an existing conveyor, the system can be operated using that conveyor’s original control panel. Automatic adjustments can be scheduled to be completed during low production times or shift changes.

Next generation CLOVER platform

CLOVER is a vendor-neutral platform that connects siloed systems and shares information across any application, database, cloud service, or application program interface (API) – whether in the cloud or on premises. The latest version further extends business processes across internal systems and related organizations, creating a shareable, digital fabric of information that enhances overall performance of a company’s product lifecycle management (PLM) system. CLOVER provides a unique job-processing architecture for a more holistic approach to building applications, minimizing customization, managing product data, and reducing total cost of ownership (TCO).

CLOVER products

CollectIT extracts, packages PLM files, data to easily share product information across the organization, to partners, suppliers

IntegrateIT exchanges files, data between PLM and other enterprise systems using advanced job processing, transformation, business rules

MigrateIT enables transfer of files and data between PLM and other enterprise systems using rehearsals, mock services, advanced error handling

PassIT provides an interface between messaging platforms and PLM systems to perform complex data transformations, file rendition creation, product revision selection, other process-oriented logic