Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

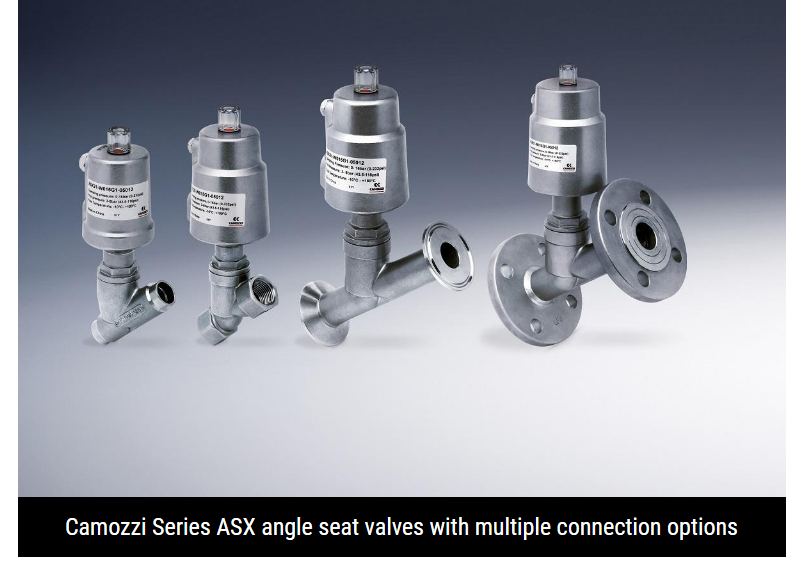

The new Series ASX pneumatically-operated angle seat valves from Camozzi Automation, have been designed to control steam, liquids, gas and fluids that contain suspended solid particulate matter.

The valve design enables a high and constant flow, whilst ensuring a low pressure drop. Many options are available with regard to nominal diameter, type of fluid and process connection type.

Made entirely of stainless steel, Series ASX offers the ideal solution for a wide variety of industrial applications where in addition to high flow rates, the ability to control viscous fluids is also a requirement. Potential user environments include steam production and water treatment plants, through to the food and chemical industries.

The two-way direct acting valves are actuated by a pressure piston and have a Y pattern body which enables a highly efficient flow rate, the seat angle being designed to enable the maximum possible flow when the orifice is open.

The valves’ 316 Stainless Steel body offers superb anti corrosion properties, with high impact resistance, even in the most demanding of applications. Installation with media below the seat can help eliminate or mitigate the troublesome issue of water hammer, which can ultimately result in noise, vibration or even pipe rupture.

Conforming to PED, ATEX, ROHS & REACH Directives, Series ASX can be used in many industrial sectors including Pulp & Paper, Chemical, Textile, Food & Beverage, Energy, Pharmaceutical & Cosmetic, Water Treatment, Air & Gas Treatment and Steam & Hot Water Treatment.