Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

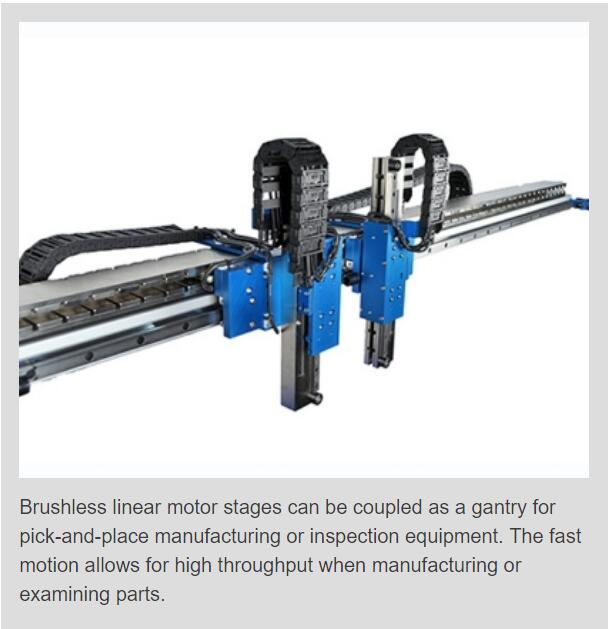

When an application requires fast motion with a stroke over a couple of inches, a brushless linear motor stage will meet the needs of long travel and fast motion when coupled with a motion control system with servo amplifiers and a motion controller. Brushless linear motor stages can be coupled as a gantry for pick-and-place manufacturing or inspection equipment. The fast motion allows for high throughput when manufacturing or examining parts.

The Four-Axis Gantry (YY'ZZ') is a four-axis positioning stage that consists of two SRS-007-03-006-01 brushless linear motor stages; each vertically mounted to two independently moving horizontal linear axis. It is ideal for applications that require multiple independent motions on a single travel plane.

Each horizontal linear axis uses a BLDM-D04 H2W brushless linear motor to generate a continuous/peak force of 16.5 lbs. [73.6 N]/49.0 lbs. [220 N] with each moving table capable of a total stroke length of 47.1 in [1196 mm]. Each moving table has an independent non-contact 1.0-micron resolution encoder head reading a single encoder scale allowing for precise positioning and is guided by a rigid recirculating ball linear bearing block sharing a single linear bearing rail.

Each vertical axis (SRS-007-03-006-01) uses a BLDM-B04 H2W brushless linear motor to generate a continuous/peak force of 6.2 lbs. [27.8 N]/18.7 lbs. [83.3 N] with a total stroke length of 7.0 in [177.8 mm]. The non-contact 1.0-micron resolution encoder allows for precise positioning. A rigid recirculating ball linear bearing guides it.

The entire stage is assembled on a single piece of aluminum extrusion, thus reducing the overall size and weight of the system. Some provisions allow customer cables to be routed within the cable carriers. It has end-of-travel rubber bumper stops. A home positioning sensor, end-of-travel sensors, and custom mounting holes on the moving tables are available upon request.