Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

Richard Davison explains how high temperature Coriolis mass flowmeters enabled a refinery to manage reprocessing of heavy crude residue

One of Europe’s leading refineries produces speciality oils, with naphthenic oils and bitumen being two of its core business products. Unlike other refineries that process lighter crudes for the production of conventional fuels, the refinery processes heavy crudes to distil its special products. To increase distillation efficiency, the slop residue of crude oil, the lighter part of crude oil obtained during the distillation process, is also reprocessed.

To better handle the variability of the slop oil before reprocessing it, the slop reflux has to be carefully controlled. Slop oil is a challenging medium. It is a thick and viscous fluid by nature and is recirculated at temperatures up to 400°C. Depending on the heaviness of crude oil, the slop reflux can also be corrosive.

The refinery had already tried to master this application using Coriolis mass flowmeters with limited success. The tested instruments were certified to only 350°C and so were often failing in the application. The systems design team was therefore searching for a reliable and accurate Coriolis mass flowmeter to be tested across the complete temperature range on one of its distillation units.

In this application, the slop oil was running at a flow rate of 270-16,000kg/h in a temperature range of 320-400°C at 3.5barg. Density was 758kg/m³ with a viscosity at operating temperature of 5cSt.

The Ideal Solution

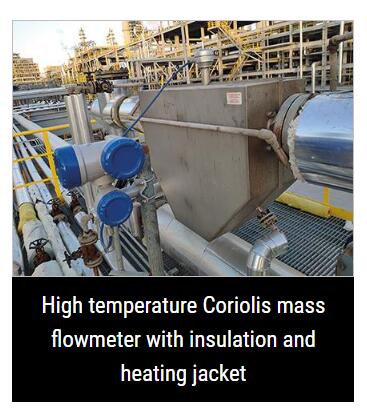

To meet these requirements, Krohne supplied an Optimass 6400 DN50 (2in) high-temperature meter in stainless steel. Tests showed that the Coriolis mass flowmeter was the flowmeter of choice in this challenging application as it delivered the required accuracy even at the maximum process temperature at 400°C. The flowmeter with twin bent tube design was installed vertically in the insulated slop reflux line.

To ensure the consistently high temperature of the medium, the flowmeter was supplied with an insulation jacket and was connected to a heating system. The Optimass 6400 was provided as a remote version with the converter to be separately installed 20m from the flow sensor.

The advanced MFC 400 converter allowed for a smooth set up and configuration. It enabled a seamless integration into the existing DCS (distributed control system) and asset management system of the customer.

The refinery was very satisfied with the flowmeter. It provided excellent accuracy and repeatability at high temperatures and handled the specific process conditions exceedingly well. It has been very robust and extremely reliable for the customer’s operations. This has enabled the system design team to model and optimise the distillation to obtain maximum process efficiency while also helping the company to troubleshoot and solve problems in the distillation column.