Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

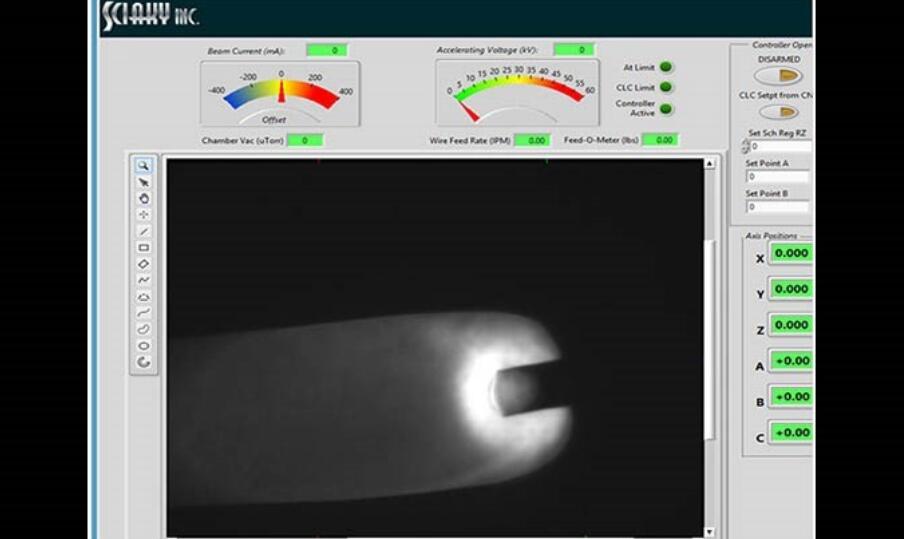

Sciaky Inc., a subsidiary of Phillips Service Industries Inc. (PSI) and supplier of industrial metal 3D printing solutions, received a Small Business Innovation Research (SBIR) award from NASA. The objective of the SBIR is to enhance Sciaky's electron beam additive manufacturing (EBAM) process with new machine-learning algorithms that automatically identify and eliminate defects with titanium (Ti-6Al-4V) 3D-printed parts and structures.

The new machine-learning algorithms will use Sciaky's patented Interlayer Real-time Imaging and Sensing System (IRISS), to monitor titanium deposition, identify anomalies, and fix them. These intuitive adaptive control features will help manufacturers deliver consistent results, from the first part to the last.

Sciaky's EBAM systems can produce parts ranging from 8" (203mm) to 19ft (5.79m) in length. EBAM has gross deposition rates up to 25 lb (11.34kg) of metal per hour.

"Sciaky is proud to partner with NASA and enhance process control for titanium 3D printing," said Scott Phillips, president and CEO of Sciaky Inc.

Sciaky's EBAM industrial metal 3D printing solution has approved applications for land, sea, air, and space.