Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

The 2018 strategic summary of U.S. defense priorities highlighted elements of defense planning that must adapt to cope with changing global realities. One of the key aspects is a shift from large, centralized infrastructure to “smaller, dispersed, resilient, adaptive basing” with the capability to “deploy, survive, operate, maneuver, and regenerate.” Maintaining force readiness under these distributed operational conditions is a logistical challenge, particularly the task of supplying spare parts for diversified forces. A comparable task presents itself in commercial aviation.

Additive manufacturing (AM) addresses that challenge by providing flexibility: a Supply Chain to the Edge™. AM that can produce a significant range of spare parts would replace the logistical challenge of maintaining a large inventory of unique parts with the relatively straightforward task of ensuring an adequate supply of raw materials. To date, AM has been too limited to fulfill that role, but the high-power blue industrial laser is pushing AM to fulfill its promise at the edge of the supply chain.

The new power of blue

When introduced, AM was primarily valued for its ability to produce plastic parts to check form, fit, and function. The technology rapidly matured with various techniques demonstrating the capability to fabricate metal parts, and laser-based methods are prized for the ease and accuracy with which they deliver energy to a target material. Unfortunately, traditional industrial lasers are absorbed poorly by industrially important metals. For 3D printing, that translates to limited speed, small production volumes, low part density, and high part cost – blue laser fixes all of that.

Copper, aluminum, stainless steel, nickel, titanium, and other metals absorb blue light better than other wavelengths, and not by a slim margin: copper absorbs blue 13x better than it absorbs infrared (IR) wavelengths. The first high-power blue industrial laser was released in 2017, and it leveraged that fundamental physical advantage to quickly make its mark in materials processing applications.

For example, the absorption advantage leads to performance benefits for copper welding. Blue welds copper 10x faster than IR. Poor IR absorption also leads to quality problems – material spatter and residual holes that degrade the mechanical and electrical integrity of the finished parts. Blue isn’t just faster than IR, it also eliminates those defects. Because other metals also absorb blue light well, the blue laser addresses the difficulty of joining dissimilar metals with quality and speed.

The same features that lead to blue’s welding performance also led to improved performance in AM, which is fundamentally the same fusing process. Blue fabricates parts faster, its low spattering leads to high-density parts, and it produces parts from dissimilar metals – a problem for alternative fabrication methods.

After initial successes welding stacks of thin copper foils, blue laser welding rapidly progressed to applications such as joining stainless steel battery casings, connecting hairpin windings in efficient electric motors, and high-volume production of components essential for cooling the electronics of 5G smartphones. That rapid progression was the result of two parallel developments: refinement of process parameters by applications engineers and continued technological advances in the capabilities of blue lasers. The technology continues to improve (see sidebar) and its impact on AM is poised to follow that same rapid trajectory.

Independent laboratory tests demonstrate that a moderate power blue laser is faster than a much higher power IR laser for metal deposition. Tests have also shown how blue can produce dense structures of copper, steel, and other metals larger than those previously produced by AM. Those early demonstrations all hinge on higher absorption at blue wavelengths.

Although laser-based AM methods vary in their details, they all require heating metals to the point where they fuse. As in welding, the key is to transfer energy from the beam to the metal. The more efficiently that can be done, the faster the process will be and the higher the quality of the finished parts. With copper, for example, reflecting more than 90% of the incident IR radiation, the efficiency is low, and the reflected light can damage the optics in the AM apparatus. Early investigations with blue have demonstrated that its productivity has greater magnitude than IR.

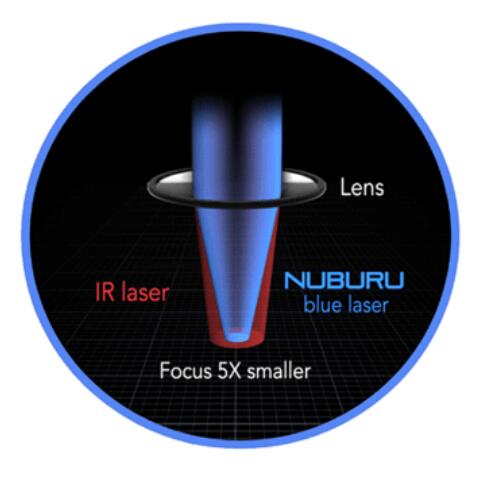

The latest advances in blue laser technology will enhance performance even more. If equivalent blue and IR beams each transmit through an identical lens, the blue spot will be less than half the size of the IR. That also means that a blue laser can produce the same size spot as an IR laser nearly 2.5x further away from the lens. For AM, that translates to a fabrication volume 10x larger than possible with IR.

Supply chain implications

Although blue laser is in its infancy, experience with welding and early investigations demonstrate the scope of the future evolution. The high-power blue laser enables:

10x faster speed

10x larger build volume

Greater part density

Accessibility to additional metals

Ability to produce bimetallic parts

These all lead to low-cost, volume manufacturing of customized parts.

Blue laser AM will simplify the logistics of supporting deployed military forces and civil aviation fleets, while simultaneously lowering costs, bringing maximum value and flexibility, and pushing the supply chain to the edge.