Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGY

Polymer bearings incorporating a PTFE-based running surface were viewed as a step forward in scroll compressor performance when they were initially introduced around three decades ago.

These polymer bearings are comprised of a polymer surface layer, a porous bronze interlayer and a steel supporting layer. This composition has grown to be prevalent in compressor applications, with continued improvements in bearing composition and performance and consequently improved environmental impact.

The application of the polymer to the bronze bearing interlayer has usually depended on the deposition of a composite slurry to create a surface that is low friction and wear-resistant.

This method of deposition has served the compressor application well, but the inherent nature of the slurry-based process meant that the lifespan of the bearing was essentially restricted by the integrity of the polymer integrity and thickness of the polymer layer.

Recent advancements have seen the development of new material technology in the scroll compressor sector. This allows bearing manufacturers to offer improvements in terms of durability and seizure resistance compared to the traditional methods of slurry-based deposition.

The resulting improvements in performance have been evidenced by means of comprehensive tribological testing in general tribological testing conditions and techniques pertinent to scroll compressor conditions.

This article outlines an assessment of bearing materials produced by multiple process technologies as well as outlining tribological results recording performance enhancement.

The test data shown includes findings from bearing development and manufacture, as well as qualification tests performed by a leading manufacturer of compressors, detailing advances in bearing durability and seizure resistance.

The successful utilization of multilayer PTFE-lined bearing materials has occurred in a wide application base. The main reason for this is the filled-PTFE running surface providing self-lubricating properties that outstrip other methods available.

The polymer’s innate low friction properties have facilitated increased efficiency where applications are affected by sliding friction and has led to reductions in wear in systems where bearings are vulnerable to adhesive wear.

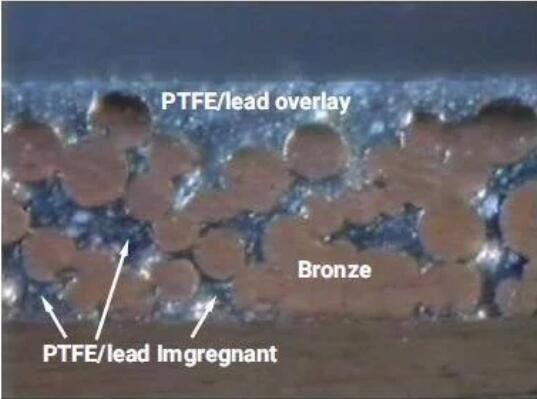

The traditional three-layer configuration for polymer bearings type consists of a porous bronze inner layer that has been sintered to a steel backing and impregnated with a filled-PTFE compound. This purposely allows a film of the same composition to remain on top.

Known as the overlay or upper layer, it is a vital element of bearing operation. A number of options are available in terms of composition:

The bearing may comprise of a PTFE and lead composition - the original multilayer polymer bearing innovation in scroll compressors.

A lead-free version that has grown in use in various applications in order to adhere to increased environmental standards.

The established manufacturing approach involved the co-coagulation of a PTFE-based aqueous dispersion that possesses the desired particulate fillers. This allows for the creation of a slurry-based compound that can be introduced into the porous bronze structure.

Further advances in the process have led to the development of a dry powder process that - along with compositional improvements - enhanced fatigue and cavitation resistance.

Modifications in size (post-installation) in powder-based or slurry-based liner methods are restricted to burnishing for both materials. The powder-based liner has been shown to be able to go through significant modification through burnishing while preserving tribological performance.

It is important to note that resizing via machining for either method led to a decreased working life for the bearing and greater friction due to the increased exposure of the bronze interlayer.

The most recent advance in the production of PTFE-based tribological layers has been a result of the process of impregnating higher-integrity polymer films.5,6 Possessing the ability to build a thicker polymer overlay, these films provide improved resistance to crucial tribological conditions such as cavitation erosion and sliding wear.

Traditionally, overlay thickness was usually in the range of 5 to 25 μm. The enhanced overlay form is ostensibly over 100 μm thickness.

A thicker overlay neutralized the sizing limitations of its predecessors, allowing machining after bearing installation to reach a level of precision comparable to that of metallic materials. It also allowed for favorable tribological advancements in a range of conditions central to the operation of scroll compressors.